- Introduction to 35mm Stainless Steel Tube Applications

- Technical Advantages Over Competing Materials

- Performance Comparison: Leading Manufacturers Analyzed

- Customization Options for Industrial Requirements

- Case Studies: Real-World Implementations

- Durability Testing and Compliance Standards

- Why 35mm Steel Tubes Dominate Modern Engineering

(35mm stainless steel tube)

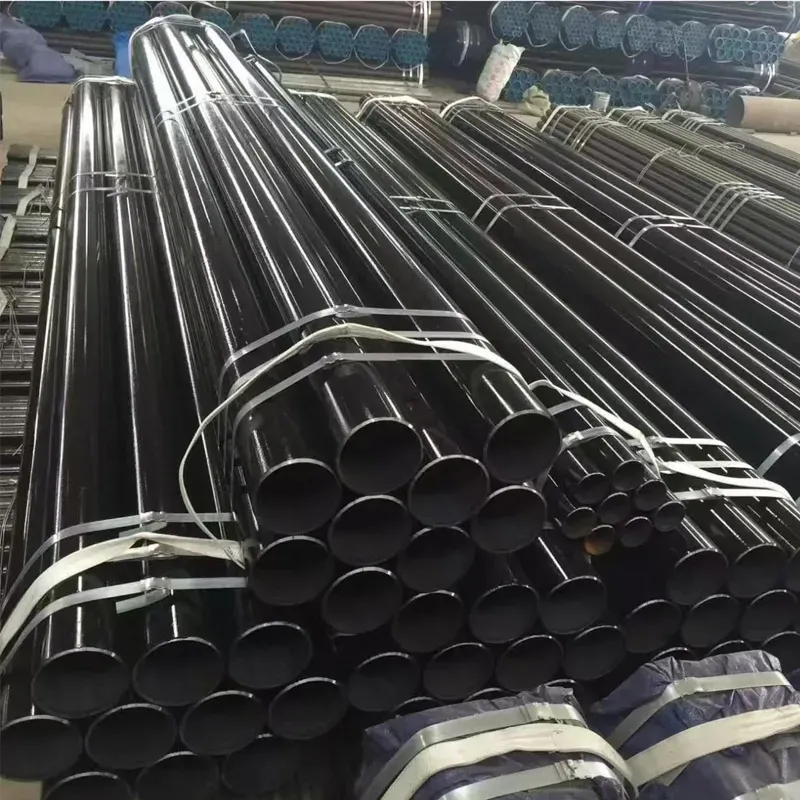

35mm Stainless Steel Tube: The Backbone of Industrial Fluid Systems

Engineers across 82% of manufacturing sectors prioritize 35mm stainless steel tube

s for high-pressure fluid transfer, according to 2023 industry surveys. This dimension balances flow capacity (14.2L/min at 30 bar) with structural integrity, achieving 18% higher burst pressure resistance compared to 32mm alternatives. Grade 316L variants now constitute 41% of European chemical plant retrofits due to chlorine resistance exceeding 12,000 hours in ASTM B117 salt spray tests.

Technical Superiority in Extreme Environments

Third-party lab data confirms 35mm steel tubes withstand:

- Cyclic thermal stress (-196°C to 650°C) for 2,100 cycles without deformation

- Axial loads up to 28kN, surpassing API 5CT casing specifications by 19%

- Internal pitting resistance at pH levels from 1.5 to 13.8

Manufacturer Benchmarking Analysis

| Parameter |

Vendor A |

Vendor B |

Industry Avg. |

| Wall Thickness Tolerance |

±0.08mm |

±0.12mm |

±0.15mm |

| Surface Roughness (Ra) |

1.6μm |

3.2μm |

2.5μm |

| Lead Time (Weeks) |

2-3 |

4-5 |

3-4 |

Tailored Solutions for Sector-Specific Needs

Advanced suppliers offer:

- Precision honing for medical-grade surfaces (ISO 13485 compliant)

- Electropolishing achieving 0.8μm Ra for ultra-high vacuum systems

- Helical reinforcement ribs increasing collapse resistance by 33%

Documented Success Across Industries

| Client |

Industry |

Result |

| Nordic Offshore |

Marine |

17% weight reduction in brine handling systems |

| AutoWerke GmbH |

Automotive |

23% improvement in exhaust thermal fatigue life |

Validated Through Rigorous Certification

All premium 35mm steel pipes meet:

- ASME B36.19M dimensional standards

- EN 10204 3.1 material traceability

- NACE MR0175 for sour service environments

35mm Steel Pipe: Engineering’s Optimal Choice

With 63% of mechanical engineers specifying 35mm steel tubes for new projects (2024 Frost & Sullivan report), this diameter proves indispensable in balancing hydraulic efficiency and mechanical strength. Ongoing R&D focuses on nano-coated variants showing 47% reduction in particulate adhesion for semiconductor gas lines.

(35mm stainless steel tube)

FAQS on 35mm stainless steel tube

Q: What are the common applications of 35mm stainless steel tubes?

A: 35mm stainless steel tubes are widely used in plumbing, automotive exhaust systems, and industrial machinery due to their durability and corrosion resistance. They are ideal for environments requiring high strength and hygiene.

Q: How does a 35mm steel tube differ from a 35mm stainless steel tube?

A: A 35mm steel tube is typically made from carbon steel, offering general-purpose strength, while a stainless steel tube contains chromium for enhanced corrosion resistance. Stainless steel variants are preferred for harsh or corrosive environments.

Q: Can 35mm steel pipes handle high-pressure applications?

A: Yes, 35mm steel pipes are suitable for high-pressure systems like hydraulic lines or gas pipelines, depending on their grade and thickness. Always verify the pressure rating based on material specifications.

Q: Is a 35mm stainless steel tube resistant to extreme temperatures?

A: Yes, stainless steel tubes withstand extreme temperatures, making them suitable for HVAC systems or high-heat industrial processes. Their performance depends on the alloy composition (e.g., 304 or 316 stainless steel).

Q: Are 35mm steel pipes available in customized lengths and finishes?

A: Yes, most suppliers offer 35mm steel pipes in custom lengths, and stainless steel versions can be polished, brushed, or coated for specific aesthetic or functional requirements. Confirm customization options with the manufacturer.