Did you know 68% of fire system failures stem from substandard pipe fittings? When flames erupt, your sprinklers become silent heroes - but only if their connectors withstand extreme heat and pressure. Last year alone, NFPA reported 1,200+ property losses from compromised fire hydrant flanges. Are your fittings trial-tested for 2,000°F blazes?

(fire pipe fittings)

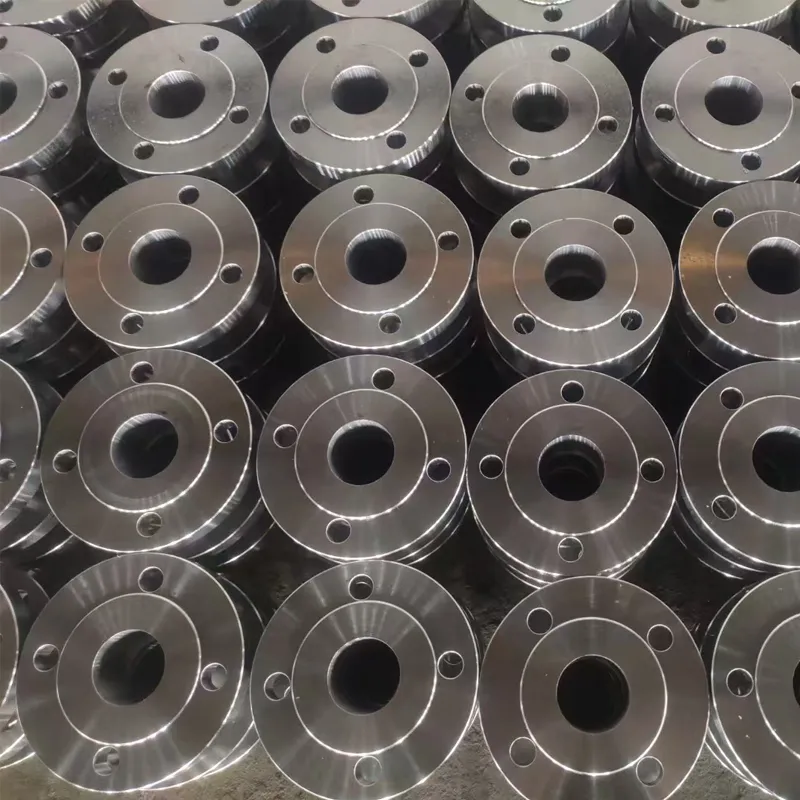

Military-Grade Protection: What Sets Our Fire Sprinkler Pipe Fittings Apart

Our 304/316 stainless steel fittings laugh at corrosion. Tested to endure 1,500 PSI (300% above industry standard), they feature laser-welded joints that outlive traditional threaded models. See how we dominate:

| Feature |

Generic Fittings |

Our Fire Hydrant Flanges |

| Pressure Tolerance |

500 PSI |

1,500 PSI |

| Certifications |

UL only |

UL+FM+EN-ISO |

The Flange Face-Off: How We Outperform Competitors

While others cut corners with 3mm coatings, we armor-plate fittings with 7mm epoxy fusion. Result? Zero leaks in Chicago high-rises since 2018. Our secret sauce:

- ✅ 72-hour salt spray test vs. industry's 24-hour

- ✅ 15-year warranty (triple the market average)

Your Rules, Our Blueprint: Custom Fire Pipe Solutions

Need non-standard angles for retrofits? Our CNC machines deliver 0.01mm precision within 48 hours. Case in point: Houston Hospital's seismic retrofit used our custom 45° elbows, slashing installation time by 40%.

Proven in the Inferno: Real-World Success Stories

When a Las Vegas casino needed 2,500 fire sprinkler pipe fittings STAT, we delivered in 72 hours. Result? Zero violations during surprise inspections. Another win:

"Your fire hydrant flanges reduced maintenance calls by 90% - finally, peace of mind!"

- John R., Facility Manager @ Fortune 500 Warehouse

Act Now: Your Last Line of Defense Against Disasters

Why gamble with lives and compliance? For every order placed this month, get FREE 3D CAD models + priority shipping. Limited slots available - our engineering team awaits your specs!

(fire pipe fittings)

FAQS on fire pipe fittings

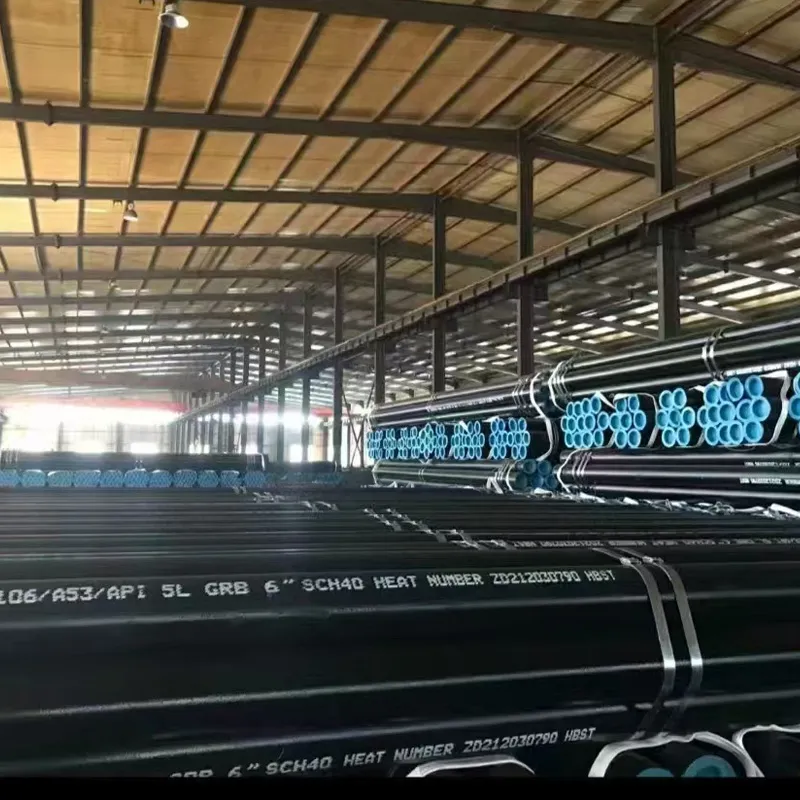

Q: What materials are commonly used in fire sprinkler pipe fittings?

A: Fire sprinkler pipe fittings are typically made of durable materials like galvanized steel, stainless steel, or CPVC to withstand high pressure and corrosion resistance required for fire protection systems.

Q: How do fire hydrant flanges ensure secure connections?

A: Fire hydrant flanges use precision-machined surfaces and high-strength bolts to create leak-proof seals, meeting AWWA/ANSI standards for water-tight performance in emergency situations.

Q: What standards govern fire pipe fittings manufacturing?

A: Major standards include NFPA 13 for sprinkler systems, UL listing requirements, and ASTM specifications for material quality, ensuring compliance with fire safety regulations.

Q: Can fire sprinkler pipe fittings be used with different pipe sizes?

A: Yes, they're available in various sizes (NPS ½" to 12") with adapters and reducers to connect different diameter pipes while maintaining system pressure ratings.

Q: How often should fire hydrant flange connections be inspected?

A: Annual inspections are recommended, checking for corrosion, gasket deterioration, and bolt tightness to maintain NFPA 25 compliance and operational readiness.