In the realm of construction, infrastructure, and various industrial applications, materials that offer strength, durability, and versatility are highly sought after. Among these, steel - based products have long held a prominent position, with steel pipes and steel tubes being key components in countless projects. From the manufacturing hubs of steel tube china to the intricate processes of steel tube design, the exploration of steel tube material and steel tube dimension reveals a complex and essential industry.

The Ubiquitous Presence of Steel Pipes

Steel pipes are integral to numerous sectors. In the oil and gas industry, for instance, they are used to transport crude oil, natural gas, and refined products over vast distances. These pipes need to withstand high pressures and harsh environmental conditions, making the choice of steel tube material crucial. High - grade steel, often with specific alloying elements, is selected to ensure the pipes' strength and corrosion resistance. In urban infrastructure, steel pipes play a vital role in water supply and sewage systems. Their durability ensures a long - lasting and reliable flow of water, while their structural integrity can withstand the weight of soil and traffic above ground. The dimensions of these pipes, falling under the category of steel tube dimension, are carefully calculated to meet the required flow capacity and pressure demands.

Steel Tube China: A Global Manufacturing Powerhouse

Steel tube china has emerged as a significant player in the global steel tube market. Chinese manufacturers leverage advanced production technologies and a large - scale industrial base to produce a wide variety of steel tubes. They cater to both domestic and international demands, supplying products for construction projects around the world. In the construction of high - rise buildings, Chinese - made steel tubes are often used for structural support. The steel tube design in these applications focuses on creating a framework that can bear heavy loads while maintaining stability. Manufacturers in China also produce specialized steel tubes for industries like automotive, where precision - engineered tubes are required for components such as exhaust systems. The quality control measures in place ensure that the steel tube material used meets international standards, making Chinese - produced steel tubes a reliable choice for global customers.

The Art and Science of Steel Tube Design

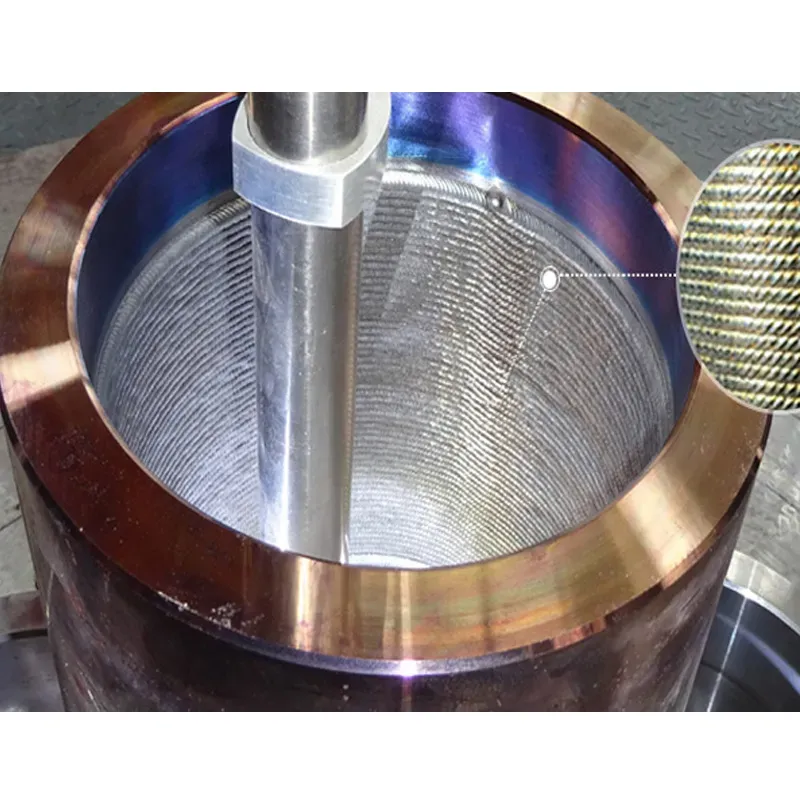

Steel tube design is a meticulous process that combines engineering principles with creative solutions. When designing steel tubes for bridge construction, engineers consider factors such as the load - bearing capacity, environmental conditions, and the aesthetic requirements of the structure. The shape and size of the tubes, which are related to steel tube dimension, are optimized to distribute forces evenly and prevent structural failure. In the aerospace industry, steel tube design focuses on creating lightweight yet strong components. Specialized alloys are selected as the steel tube material to achieve the necessary strength - to - weight ratio. Computer - aided design (CAD) software is often employed to simulate the performance of the tubes under different conditions, allowing designers to make precise adjustments before production begins.

Understanding Steel Tube Material

The choice of steel tube material is a critical factor in determining the performance and lifespan of steel tubes. Carbon steel is one of the most commonly used materials due to its relatively low cost and good mechanical properties. It is suitable for applications where high strength and durability are required, such as in the construction of industrial pipelines. Stainless steel, on the other hand, is preferred for its excellent corrosion resistance, making it ideal for use in environments where exposure to moisture, chemicals, or saltwater is common, like in marine applications or food processing facilities. Alloy steels, which contain additional elements such as chromium, nickel, and molybdenum, offer enhanced properties such as increased hardness, wear resistance, and high - temperature strength. The selection of the appropriate steel tube material depends on the specific requirements of the application, including the operating conditions, load requirements, and cost considerations.

The Significance of Steel Tube Dimension

Steel tube dimension encompasses various aspects, including outer diameter, inner diameter, and wall thickness. In heat exchanger applications, the precise steel tube dimension is crucial for efficient heat transfer. Smaller - diameter tubes can increase the surface area for heat exchange, while the wall thickness affects the tube's strength and thermal conductivity. In the scaffolding industry, the dimensions of steel tubes determine the stability and load - bearing capacity of the scaffolding structure. Standardized steel tube dimension systems ensure compatibility between different components, allowing for easy assembly and disassembly. Additionally, in the manufacturing of furniture, the dimensions of steel tubes are carefully chosen to achieve the desired aesthetic and structural balance, combining functionality with design.

FAQs about Steel Tubes and Pipes

How to Select the Appropriate Steel Tube Material for a Project?

Selecting the right steel tube material requires a comprehensive understanding of the project's requirements. First, assess the environmental conditions the tubes will be exposed to, such as temperature, humidity, and chemical exposure. For example, in a coastal area, stainless steel might be a better choice due to its corrosion resistance. Then, consider the load - bearing requirements. High - strength alloy steels may be necessary for applications with heavy loads. Cost is also a factor; carbon steel is often more budget - friendly but may not be suitable for all applications. Consult with material experts or refer to industry standards and guidelines to make an informed decision.

What Are the Common Standards for Steel Tube Dimension?

There are several international and national standards for steel tube dimension. The American Petroleum Institute (API) sets standards for steel pipes used in the oil and gas industry, specifying dimensions for different pipe sizes and wall thicknesses. The International Organization for Standardization (ISO) also has standards that cover a wide range of steel tube dimensions, ensuring consistency and compatibility across different regions. In China, the Chinese National Standards (GB) define the dimensions for various types of steel tubes produced domestically. Adhering to these standards is important for ensuring the quality and interchangeability of steel tubes in different projects.

How Does Steel Tube Design Impact the Manufacturing Process?

The steel tube design has a significant impact on the manufacturing process. Complex designs with unique shapes or special features may require specialized manufacturing techniques and equipment. For example, tubes with intricate bends or custom - shaped cross - sections may need to be formed using advanced bending or extrusion processes. The design also affects the cutting and welding operations. Precise designs may require more accurate cutting and higher - quality welding to ensure the structural integrity of the tubes. Additionally, the design can influence the production efficiency; simpler designs are generally easier and faster to manufacture, reducing production costs.

Can Steel Tubes from China Meet International Quality Requirements?

Yes, many steel tubes produced in steel tube china meet international quality requirements. Chinese manufacturers have made significant investments in technology, quality control systems, and research and development. They often comply with international standards such as ISO, API, and ASTM. Many Chinese steel tube manufacturers also hold international certifications, which demonstrate their ability to produce high - quality products. However, as with any market, it's important for buyers to conduct due diligence, choose reputable suppliers, and verify the quality of the products through proper inspection and testing before making a purchase.

What Are the Emerging Trends in the Steel Tube and Pipe Industry?

The steel tube and pipe industry is witnessing several emerging trends. There is an increasing demand for more sustainable and environmentally friendly steel tube material. Manufacturers are exploring ways to reduce the carbon footprint of steel production, such as using recycled materials and more energy - efficient processes. In terms of steel tube design, there is a focus on creating lighter - weight yet stronger tubes through the use of advanced alloys and innovative geometries. Additionally, the use of smart technologies, such as sensors embedded in steel tubes to monitor their condition in real - time, is becoming more prevalent, especially in critical infrastructure applications.