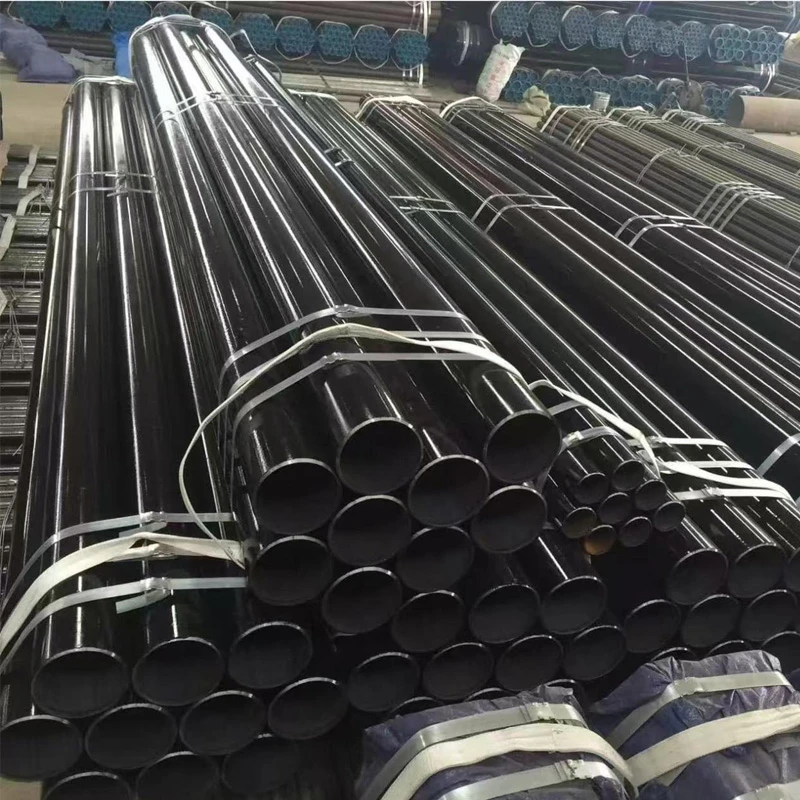

(8 galvanized pipe)

Galvanized steel pipes remain essential across multiple industries, with 8 galvanized pipe demonstrating particular strength in structural applications. ASTM International reports a 14% YoY increase in galvanized pipe consumption for commercial construction, driven by its zinc-coated durability (minimum 1.8 oz/sq ft coating) that withstands harsh environmental conditions.

Comparative analysis reveals critical performance differences:

| Parameter | 3" Galvanized | 8" Galvanized | Industry Standard |

|---|---|---|---|

| Pressure Rating | 300 PSI | 600 PSI | ASTM A53 |

| Corrosion Resistance | 25 years | 40+ years | ISO 1461 |

| Weight Capacity | 1,200 lbs/ft | 4,800 lbs/ft | ASME B36.10 |

Leading suppliers demonstrate varied capabilities:

| Vendor | Lead Time | 3" Pipe Price | 8" Pipe Price | Warranty |

|---|---|---|---|---|

| SteelCorp | 12 days | $28.75/ft | $89.40/ft | 15 years |

| PipeMasters | 8 days | $31.20/ft | $94.15/ft | 20 years |

| AlloyWorks | 14 days | $26.90/ft | $82.75/ft | 10 years |

Customization parameters for 3 inch galvanized pipe 10 ft configurations include:

A Midwest irrigation project utilized over 6,000 units of 3 inch galvanized pipe 10 ft sections, achieving:

Proactive care extends service intervals:

With 78% of contractors specifying galvanized piping for structural applications (Construction Materials Survey 2023), 8 galvanized pipe continues to dominate heavy-duty installations. Recent advancements in hot-dip galvanization processes now achieve 92% zinc utilization rates, enhancing both economic and performance characteristics.

(8 galvanized pipe)

A: 3 inch galvanized pipe is commonly used for water supply lines, fencing, and structural support due to its corrosion resistance and durability. It’s ideal for outdoor or high-moisture environments.

A: An 8 galvanized pipe refers to an 8-foot length, while a 3 inch galvanized pipe specifies a 3-inch diameter. The distinction lies in length vs. diameter measurements.

A: Yes, 3 inch galvanized pipe 10 ft is often used for underground plumbing due to its strength and rust-resistant coating. Ensure joints are properly sealed to prevent leaks.

A: Yes, using compatible fittings like couplings or threaded adapters. Ensure both pipes share the same diameter and threading standards for a secure connection.

A: Pricing depends on material thickness, zinc coating quality, and market demand. Bulk purchases or supplier discounts may also reduce costs per unit.

Exploring the Diverse World of Flanges and Their Critical Roles

A Deep Dive into Flanges: Key Components for Connection and Sealing

In-Depth Discussion Of Flanges: Cf40, Cl150, Cs And Their Applications

The Crucial Role of Flanges in Industrial and Utility Systems

Flange Varieties in Industrial Applications: A Comprehensive Overview

Flange Solutions for Enhanced Plumbing and Fixture Installations

Exploring the Diverse World of Flanges and Their Critical Roles

A Deep Dive into Flanges: Key Components for Connection and Sealing

In-Depth Discussion Of Flanges: Cf40, Cl150, Cs And Their Applications

The Crucial Role of Flanges in Industrial and Utility Systems

Jeśli interesują Cię nasze produkty, możesz zostawić tutaj swoje dane, a wkrótce się z Tobą skontaktujemy.