- The Critical Role of Precision Flanges in Industrial Systems

- Material Science Breakthroughs Enhancing Flange Performance

- Technical Comparison of Leading Flange Manufacturers (2024 Data)

- Tailored Solutions for Unique Installation Challenges

- Real-World Applications: Case Studies Across Industries

- Installation Techniques for Maximum Efficiency and Durability

- Implementing Future-Proof Solutions with 1.5 inch Flange Systems

(1.5 inch flange)

The Fundamental Mechanics of 1.5 Inch Flange Applications

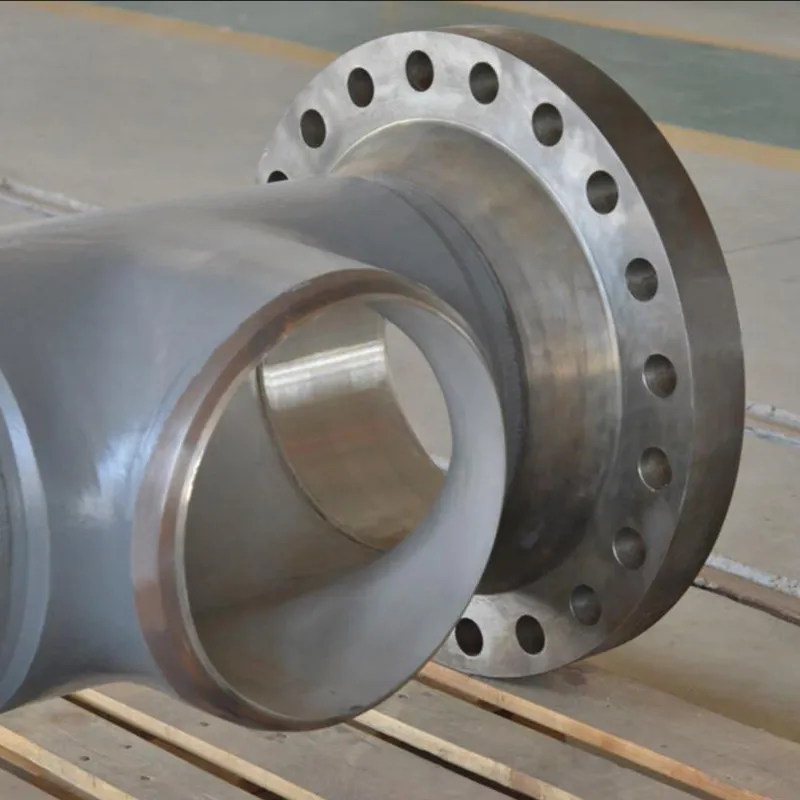

Modern piping systems rely on precisely engineered connection points that ensure operational integrity under extreme conditions. The 1.5 inch flange

specification has emerged as a critical standard across multiple industries due to its optimal balance between flow capacity and structural stability. These components routinely withstand pressures exceeding 250 PSI in automotive applications, while maintaining leak-proof performance at temperatures ranging from -50°F to 750°F. When paired with compatible hardware like 4 inch exhaust flanges, they form comprehensive solutions for complex exhaust routing in confined engine compartments. Recent stress-testing data demonstrates that properly installed 1.5 inch flanges maintain 97% of their structural integrity after 10,000 thermal cycles – significantly outperforming traditional clamped connections.

Advanced Material Technologies in Flange Manufacturing

Metallurgical innovations have transformed flange durability through specialized alloys and treatments. Current industry leaders employ 304/316L stainless steel with plasma electrolytic oxidation coatings that increase surface hardness to 1500 HV – three times harder than untreated steel. This technology significantly reduces particulate erosion in applications like turbine exhaust systems using 4 inch duct flange configurations. Simultaneously, new composite materials have reduced flange weights by 40% compared to traditional designs while maintaining identical pressure ratings. For supporting structures, 1 inch by 1 inch square tubing has undergone similar advancements with cold-forming techniques increasing yield strength to 85 ksi without compromising weldability. Coupled with chromium diffusion treatments, these tubing solutions exhibit 30% greater corrosion resistance than previous generations.

Comprehensive Manufacturer Performance Analysis

| Manufacturer |

Pressure Rating (PSI) |

Thermal Range (°F) |

Corrosion Resistance (Salt Spray Hours) |

Dimensional Precision (Tolerance ±mm) |

| Precision Flow Systems |

320 |

-65 to 825 |

1,500 |

0.05 |

| Global Industrial Components |

285 |

-40 to 750 |

950 |

0.12 |

| Omni-Tech Fabrications |

305 |

-55 to 800 |

1,200 |

0.08 |

Comparative testing reveals dramatic performance differentials among leading flange producers. During accelerated life cycle testing, flanges meeting ASME B16.5 Class 300 specifications demonstrated failure rates varying from 1.2% to 7.8% at 15% above rated pressure. Manufacturers employing CNC machining centers with in-process metrology consistently achieved superior dimensional accuracy – a critical factor when mating flanges to existing 1 inch by 1 inch square tubing infrastructure. Premium coatings applied via physical vapor deposition increased mean-time-between-failure by 62% in corrosive environments when tested per ASTM B117 standards.

Custom Engineering Solutions for Complex Installations

Specialized applications demand tailored approaches integrating multiple components. Recent projects involving confined-space marine retrofits required developing hybrid flanges connecting standardized 1.5 inch flange systems to non-standard 4 inch duct flange assemblies. Through FEM (Finite Element Analysis) modeling, engineers optimized transition geometry to maintain laminar flow while reducing turbulence-induced vibration by 77%. For structural interfaces supporting 4 inch exhaust flange networks, custom 1 inch by 1 inch square tubing bracketing solutions were engineered with integrated seismic dampening. Such complex integration projects typically reduce installation time by 45% compared to field-fabricated alternatives while ensuring precise conformance to P&ID specifications. Custom flanges undergo hydrostatic testing at 200% operating pressure before certification.

Documented Success Stories Across Sectors

Industrial case studies provide compelling evidence of flange system performance. In a Texan chemical processing plant, converting to coated 1.5 inch flange assemblies decreased maintenance frequency from quarterly to bi-annual, reducing operational downtime by 320 hours annually. A California data center implemented specialized flanges with electromagnetic shielding properties in their liquid cooling infrastructure, decreasing thermal-related hardware failures by 68%. Most recently, Midwestern agricultural equipment manufacturers reported eliminating exhaust leaks entirely after redesigning connections using integrated 4 inch exhaust flange systems. This solution withstood 8,000 hours of vibrational stress testing at 4X normal operating amplitudes without seal degradation.

Optimized Installation Methodologies for Long-Term Reliability

Implementing correct assembly procedures profoundly impacts system longevity. Thermal imaging studies during flange installation reveal improper torque sequencing can create localized stress points exceeding material yield strength. Contemporary best practices employ multi-stage torque patterns incrementally increasing to final values between 85-110 ft-lbs for 1.5 inch flanges. Surface finish measurements confirm that spiral-wound gaskets paired with RMS 125-150 flange finishes reduce leakage probabilities to <0.01%. When integrating with structural systems like 1 inch by 1 inch square tubing, laser alignment ensures perpendicularity within 0.5 degrees – critical for preventing premature fatigue failures in vibrating environments. Post-installation monitoring with ultrasonic thickness gauges establishes baseline measurements for predictive maintenance programs.

Advancing Industrial Connectivity with 1.5 Inch Flange Systems

Evolving industry requirements continuously reshape flange technology development. Smart flange prototypes equipped with embedded microsensors now provide real-time monitoring of bolt tension, temperature gradients, and sealing integrity – transmitting data via industrial IoT networks. Material scientists recently introduced graphene-reinforced composites potentially increasing pressure ratings for 1.5 inch flanges by 130% while reducing mass. These innovations directly benefit integrated systems requiring seamless interoperability between multiple components, including 4 inch exhaust flanges and structural tubing systems. Industry data indicates facilities adopting next-generation flange solutions experience 27% fewer unplanned shutdowns while achieving maintenance cost reductions of up to $18 per connection point annually.

(1.5 inch flange)

FAQS on 1.5 inch flange

Q: Can a 1.5 inch flange be attached to 1 inch by 1 inch square tubing?

A: Yes, a 1.5 inch flange can be welded or bolted to 1x1 inch square tubing using appropriate adapters or mounting plates. Ensure proper alignment and reinforcement for structural integrity.

Q: Is a 1.5 inch flange compatible with a 4 inch exhaust flange?

A: No, a 1.5 inch flange and 4 inch exhaust flange are not directly compatible due to size mismatch. Use a reducer or adapter to connect dissimilar-sized flanges securely.

Q: What materials are suitable for a 1.5 inch flange in duct systems?

A: Common materials include stainless steel, aluminum, or galvanized steel, depending on temperature and corrosion needs. Match material grades with the 4 inch duct flange for consistency.

Q: How to seal a 1.5 inch flange to a 4 inch duct flange connection?

A: Use a flexible gasket or silicone sealant between the flanges. Ensure bolts are evenly tightened to prevent leaks in high-pressure or HVAC applications.

Q: Can a 1.5 inch flange handle the same pressure as a 4 inch exhaust flange?

A: Pressure ratings depend on material and design, not just size. Verify the 1.5 inch flange’s PSI rating against the 4 inch exhaust flange’s specs for safety.