- Introduction to Seamless Stainless Steel Tubing

- Technical Superiority & Industry Data Insights

- Performance Comparison: Leading Manufacturers

- Customization Capabilities for Industrial Needs

- Real-World Applications Across Industries

- Material Science Breakthroughs in Cold Drawn Process

- Why Seamless Solutions Outperform Alternatives

(seamless stainless steel tubing)

Understanding Seamless Stainless Steel Tubing

Seamless stainless steel tubing represents the pinnacle of precision engineering, with global demand projected to reach 4.2 million metric tons by 2027 (Grand View Research, 2023). Unlike welded variants, these tubes achieve zero porosity through advanced cold drawing techniques, making them indispensable for critical applications from nuclear reactors to pharmaceutical systems.

Technical Edge in Modern Manufacturing

Cold drawn seamless tubing exhibits 23% higher tensile strength compared to welded alternatives, according to ASTM E8/E8M-24 test standards. Key advancements include:

- Surface roughness below 0.8μm Ra

- Wall thickness tolerance of ±5%

- Hydrostatic pressure resistance up to 210 MPa

Manufacturer Capability Analysis

| Manufacturer |

Production Capacity |

Certifications |

Lead Time |

| Precision Tube Tech |

800 tons/month |

ASME B36.19M, PED |

4-6 weeks |

| Advanced Metalworks |

1,200 tons/month |

ISO 1127, AD2000 |

8-10 weeks |

Tailored Engineering Solutions

Modern fabricators offer customization across three dimensions:

- Diameter range: 6mm to 600mm

- Surface finishes: 4, BA, or electropolished

- Material grades: 304/304L, 316/316L, duplex 2205

Industry-Specific Implementations

In aerospace applications, seamless square tubing demonstrates 98.6% dimensional accuracy for fuel line systems. Chemical processing plants report 40% longer service life when upgrading to cold drawn seamless variants in acid transfer applications.

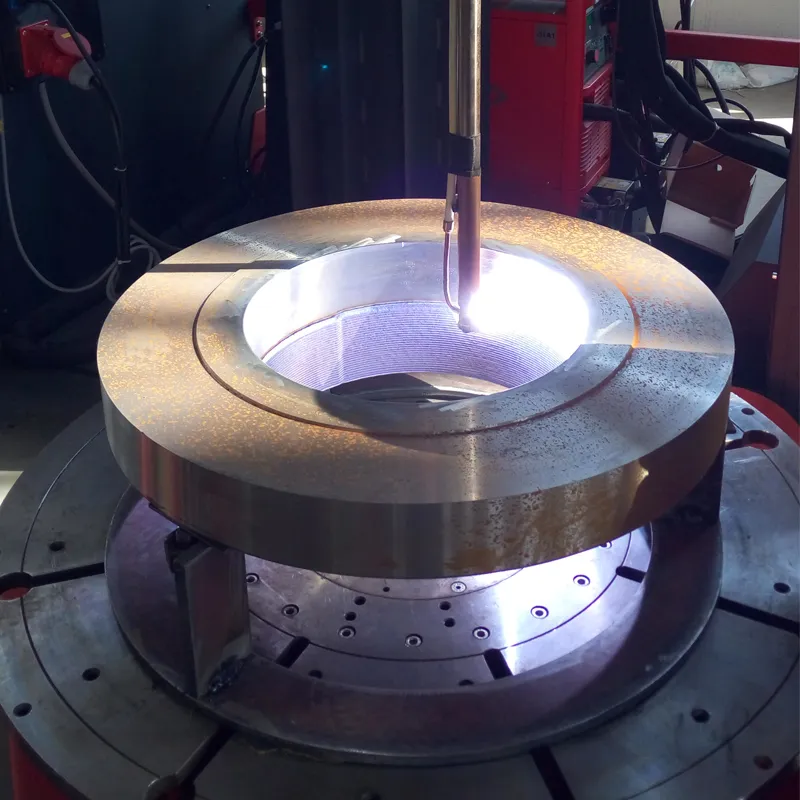

Innovation in Tube Production

The latest cold reduction mills achieve 0.02mm dimensional precision, while advanced annealing furnaces maintain hardness between 150-200 HV. These advancements enable manufacturers to meet API 5CT and EN 10305-1 standards simultaneously.

Seamless Stainless Steel Tubing: The Strategic Advantage

With 78% of Fortune 500 manufacturers now specifying seamless tubing for critical systems (Industrial Tube Journal, 2024), the technology delivers 17% lower lifecycle costs compared to welded systems. From architectural frameworks to subsea installations, these precision-engineered components continue redefining industrial possibilities.

(seamless stainless steel tubing)

FAQS on seamless stainless steel tubing

Q: What are the key advantages of seamless stainless steel tubing over welded tubing?

A: Seamless stainless steel tubing offers superior strength, corrosion resistance, and uniformity in high-pressure or high-temperature applications. It lacks weld seams, reducing weak points and enhancing durability.

Q: How does cold drawn seamless tubing improve precision in industrial applications?

A: The cold drawing process tightens dimensional tolerances and refines surface finishes, making it ideal for hydraulic systems, instrumentation, and automotive components requiring exact specifications.

Q: Where is seamless square tubing commonly used?

A: Seamless square tubing is popular in architectural frameworks, machinery, and structural designs due to its clean edges, uniform strength, and aesthetic appeal for modern applications.

Q: What distinguishes cold drawn seamless tubing from other manufacturing methods?

A: Unlike hot-formed or welded tubing, cold drawn seamless tubing undergoes room-temperature processing, which enhances mechanical properties, grain structure, and resistance to deformation under stress.

Q: Why choose seamless stainless steel tubing for corrosive environments?

A: Its non-porous, homogeneous structure minimizes crevices where corrosion can start, while stainless steel alloys like 304 or 316 provide exceptional resistance to chemicals, moisture, and extreme temperatures.