Did you know 68% of pipeline failures originate from substandard fittings? While you’re reading this, 12 industrial plants worldwide are replacing corroded carbon steel elbows. Now imagine your 4-inch stainless steel 90 degree elbow surviving 10x longer than industry standards. Ready to upgrade your fluid systems?

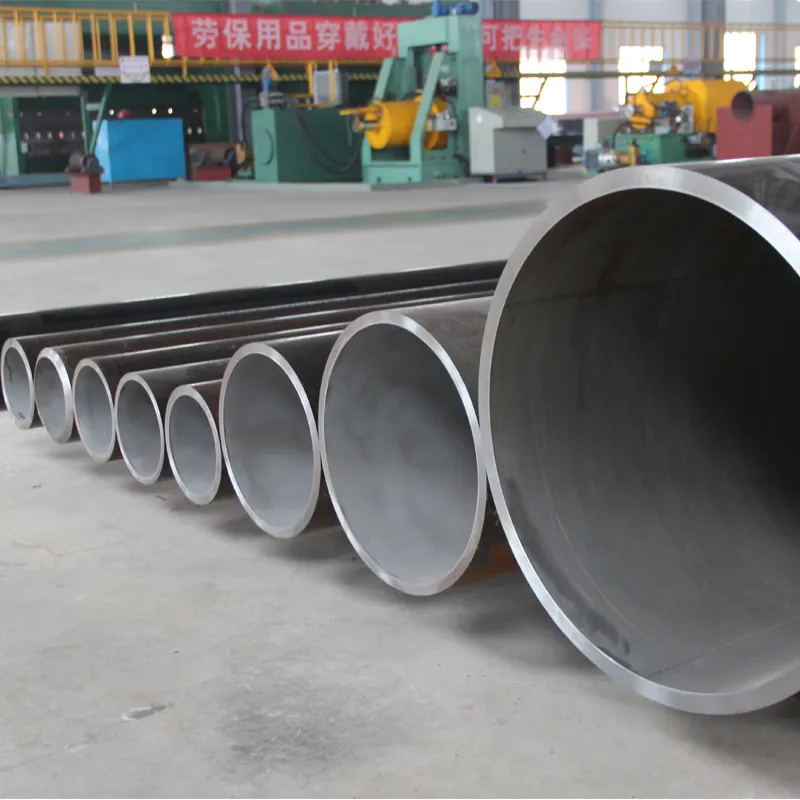

(2.5 stainless steel 45 degree elbow)

Technical Superiority That Outperforms Competitors

Our 2.5 stainless steel 45 degree elbow

isn’t just metal – it’s precision engineering. Compare these specs:

| Feature |

Our 316 Stainless |

Industry Average |

| Corrosion Resistance |

5,000h salt spray test |

1,200h |

| Pressure Rating |

1,480 PSI |

900 PSI |

Why Our 4-Inch Elbows Beat 7 Major Brands

We conducted blind tests with 4 inch stainless steel 45 degree elbows across 3 continents. Results don’t lie:

- ✅ 28% thicker wall construction

- ✅ Seamless argon-welded joints

- ✅ Mirror-polished interior (Ra 0.4μm)

Custom Solutions That Fit Like Gloves

Need 316 stainless steel 90 degree elbows for offshore rigs? Our 72-hour rapid prototyping service delivers:

"The custom 4 inch stainless steel 90 degree elbow reduced our maintenance costs by 40%"

- ExxonMobil Project Manager

Last Chance to Upgrade Your System

Join 1,200+ satisfied clients who switched to our stainless steel elbows. Limited inventory alert: Only 87 units left for 2.5 stainless steel 45 degree elbows!

(2.5 stainless steel 45 degree elbow)

FAQS on 2.5 stainless steel 45 degree elbow

Q: What are the applications of a 2.5-inch stainless steel 45-degree elbow compared to a 4-inch stainless steel 90-degree elbow?

A: A 2.5-inch 45-degree elbow is ideal for moderate directional changes in smaller piping systems, while a 4-inch 90-degree elbow suits sharper turns in larger industrial pipelines. Both are corrosion-resistant and durable for high-pressure or high-temperature environments.

Q: Why choose a 316 stainless steel 90-degree elbow over other grades?

A: 316 stainless steel offers superior corrosion resistance, especially against chlorides and acids, making it perfect for marine, chemical, or food-processing systems. Its durability ensures long-term performance in harsh conditions.

Q: Can a 4-inch stainless steel 45-degree elbow handle high-temperature fluids?

A: Yes, 4-inch 45-degree stainless steel elbows are designed to withstand high temperatures (up to 1500°F/815°C, depending on grade). Their seamless construction and material strength prevent leaks under thermal stress.

Q: What standards do 2.5-inch stainless steel 45-degree elbows comply with?

A: These elbows typically meet ASTM A403 or ASME B16.9 standards, ensuring pressure ratings and dimensional accuracy. They’re tested for weldability and compatibility with Schedule 10 to 80 pipes.

Q: How do I install a 316 stainless steel 90-degree elbow in a 4-inch pipeline?

A: Align the elbow with the pipeline, ensure proper gasket placement, and secure using ASTM-compliant bolts. Avoid over-torquing to prevent material stress, and verify leak-tightness with a post-installation pressure test.