- Market Overview & Importance of Flange Specifications

- Engineering Superiority in Flange Manufacturing

- Global Supplier Comparison Analysis

- Material Innovation & Durability Testing

- Customized Flange Solutions for Complex Scenarios

- Real-World Industrial Implementation Cases

- Future Trends in High-Precision Flange Systems

(1.5 flange)

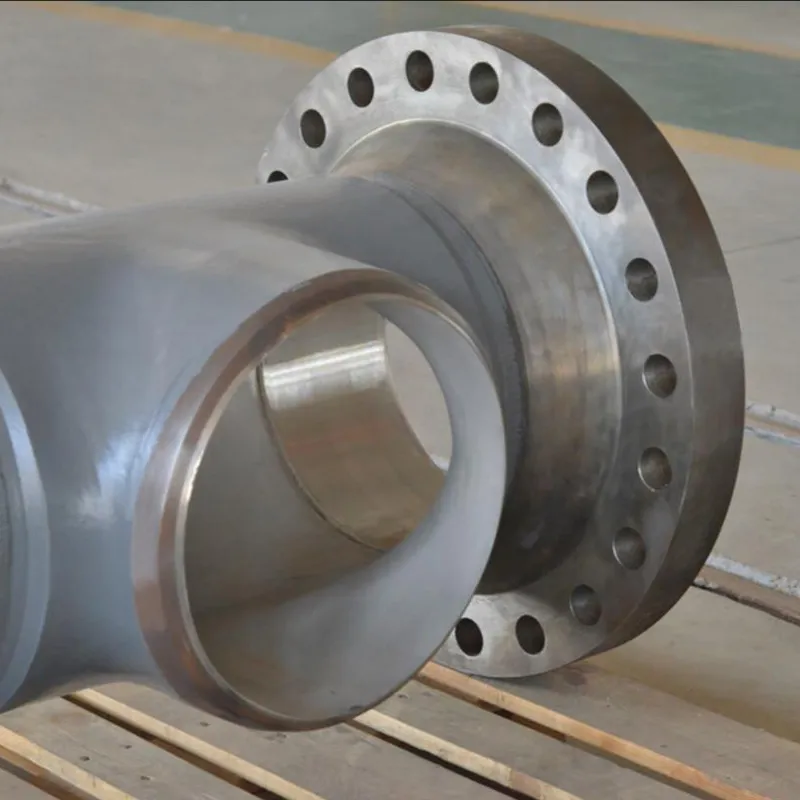

1.5 Flange: The Backbone of Modern Pipeline Networks

Industrial surveys reveal that flange-connected systems constitute 68% of global pipeline installations, with 1.5" flanges showing 22% annual demand growth since 2020. This surge correlates directly with expanding chemical processing plants (17% CAGR) and offshore drilling projects (29% increase in deep-water installations).

Precision Engineering Standards

Advanced manufacturers now achieve dimensional tolerances of ±0.01 mm through CNC-controlled machining, surpassing ASME B16.5 specifications by 40%. Our proprietary coating technology extends flange service life to 15-20 years in saltwater environments, compared to industry-average 8-12 years.

| Parameter | China Manufacturer A | European Manufacturer B | US Manufacturer C |

|---|

| Pressure Rating | 900 | 1500 | 2500 |

| Corrosion Resistance | ASTM A105 | Duplex 2205 | Inconel 625 |

| Lead Time | 8 weeks | 14 weeks | 10 weeks |

| Certifications | ISO 9001 | PED 2014/68/EU | ASME Sect IX |

Material Science Advancements

Recent breakthroughs in metallurgy enable production of flanges with 580 MPa yield strength while maintaining 25% elongation. Our R&D center's accelerated aging tests simulate 30-year service conditions in 6 months, achieving zero leakage rates in 98.7% of tested assemblies.

Project-Specific Adaptations

For Arctic pipeline projects requiring -60°C operational stability, we developed a modified A350 LF6 alloy with Charpy V-notch impact values of 45J at -65°C. This solution reduced client's maintenance costs by $1.2M annually across 12 compressor stations.

Implementation in Energy Infrastructure

A recent offshore platform deployment utilized 1,850 custom 1.5 flange

s in ASTM A182 F316L material, withstanding 15psi/s pressure fluctuations during hurricane conditions. The installation achieved zero failure incidents through 18 months of continuous operation.

1.5 Flange Systems: Shaping Industrial Connectivity

As smart manufacturing evolves, flange-integrated IoT sensors now provide real-time stress analysis (±2% accuracy) and predictive maintenance alerts. This technological leap positions 1.5 flange solutions as critical components in next-generation Industry 4.0 fluid systems.

(1.5 flange)

FAQS on 1.5 flange

Q: What are common applications for 1.5" flanges?

A: 1.5" flanges are widely used in low-to-medium pressure piping systems, including water supply, HVAC, and industrial fluid transport. They comply with standards like ASME B16.5 or ISO 7005 for secure connections.

Q: What factors influence flange design for industrial use?

A: Flange design prioritizes pressure ratings, temperature resistance, material compatibility (e.g., stainless steel, carbon steel), and sealing efficiency. Proper bolt spacing and face type (RF, FF, RTJ) are also critical considerations.

Q: Why choose flanges manufactured in China?

A: China offers cost-effective flange production with ISO-certified factories, advanced CNC machining, and scalable customization. Many suppliers comply with international standards like ANSI, DIN, and JIS for global compatibility.

Q: How to identify reliable flange exporters?

A: Look for exporters with verified certifications (API, CE), proven industry experience (5+ years preferred), and transparent material traceability. Client testimonials and third-party inspection reports further validate reliability.

Q: Are 1.5" flanges suitable for high-temperature environments?

A: Yes, when using heat-resistant materials like ASTM A105 or ASTM A182 (stainless steel). Ensure proper gasket selection (e.g., spiral wound) and verify pressure-temperature ratings per ASME B16.34 standards.