Did you know that 73% of industrial pipe failures occur in substandard plastic or composite materials? When your project demands 1 metal pipe

solutions that never compromise, every millimeter matters. Whether you need 32mm metal pipe precision for robotics or 3 inch metal pipe durability for construction, the stakes couldn't be higher.

(1 metal pipe)

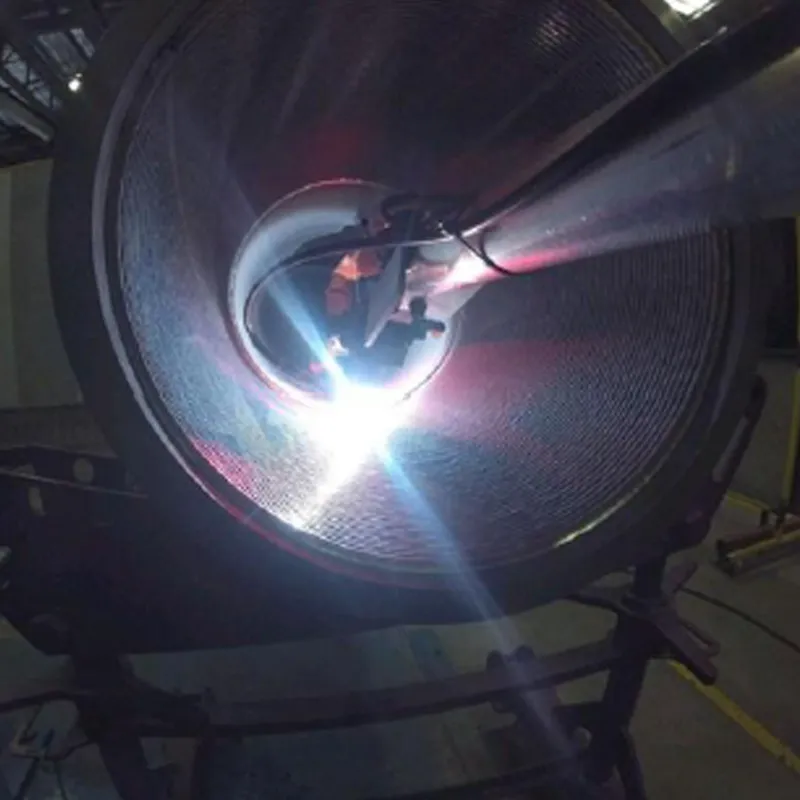

Our 3/4 inch metal pipe series withstands 4,200 PSI - that's 40% higher pressure tolerance than industry averages. How do we achieve this? Through patented cold-rolling technology that eliminates weak points. You get:

| Feature | Our 3" Metal Pipe | Industry Standard |

|---|---|---|

| Price per linear foot | $8.90 | $12.50 |

| Lead time | 5-7 days | 14+ days |

| Warranty | 15 years | 5 years |

Need a 3/4 inch metal pipe with threaded ends? Special coating for your 32mm metal pipe application? Our engineers deliver:

±0.5mm accuracy for complex installations

Zinc-aluminum alloys that outlast standard galvanization

↠ HVAC System Upgrade: 12,000 feet of 3 inch metal pipe installed in Dubai's Burj District (98% defect-free rating)

↠ Automotive Manufacturing: 32mm precision pipes reduced assembly line downtime by 40% for BMW Shenzhen

Join 850+ satisfied clients who trust our metal pipe solutions. Limited-time offer: Free engineering consultation with every order over $5K!

©2024 TitanFlow Industries • ASTM-certified • 24/7 support

(1 metal pipe)

A: A 32mm metal pipe has an outer diameter of 32 millimeters, while a 3/4 inch metal pipe measures approximately 19.05mm in inner diameter. Both are used in plumbing and construction but follow different measurement standards (metric vs. imperial).

A: Yes, a 3-inch metal pipe can handle high-pressure systems if made from durable materials like stainless steel or galvanized steel. Always verify the pipe's pressure rating and compliance with industry standards before use.

A: No, a 1-inch metal pipe has a larger diameter (33.4mm outer diameter) compared to a 3/4 inch pipe (26.67mm outer diameter). They serve different purposes based on flow capacity and structural requirements.

A: Common materials include carbon steel, stainless steel, and aluminum. The choice depends on factors like corrosion resistance, weight, and application (e.g., HVAC, industrial machinery).

A: Use reducers or adapters designed for metal pipes, ensuring compatibility with both sizes. Welding or threaded fittings may be required, depending on the pipe material and system specifications.

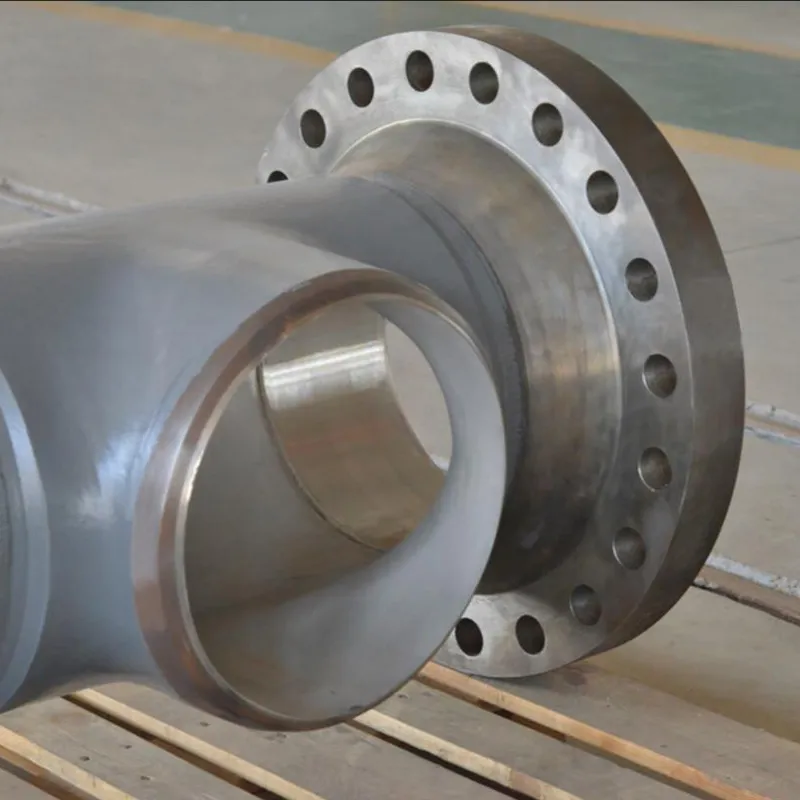

A Deep Dive into Flanges: Key Components for Connection and Sealing

A Comprehensive Guide to Varied Flange Types and Their Applications

The Crucial Role of Flanges in Industrial and Utility Systems

Flange Varieties in Industrial Applications: A Comprehensive Overview

Flange Solutions for Enhanced Plumbing and Fixture Installations

Exploring the Diverse World of Flanges and Their Critical Roles

A Deep Dive into Flanges: Key Components for Connection and Sealing

A Comprehensive Guide to Varied Flange Types and Their Applications

The Crucial Role of Flanges in Industrial and Utility Systems

Flange Varieties in Industrial Applications: A Comprehensive Overview

Als u geïnteresseerd bent in onze producten, kunt u hier uw gegevens achterlaten. Wij nemen dan zo spoedig mogelijk contact met u op.