Did you know 32% of industrial accidents stem from substandard piping systems? Every day, engineers like you battle corrosion leaks, fitting mismatches, and delivery delays. But what if you could slash maintenance costs by 40% while boosting project durability? Let's explore how partnering with the right steel pipe factory

transforms these pain points into competitive advantages.

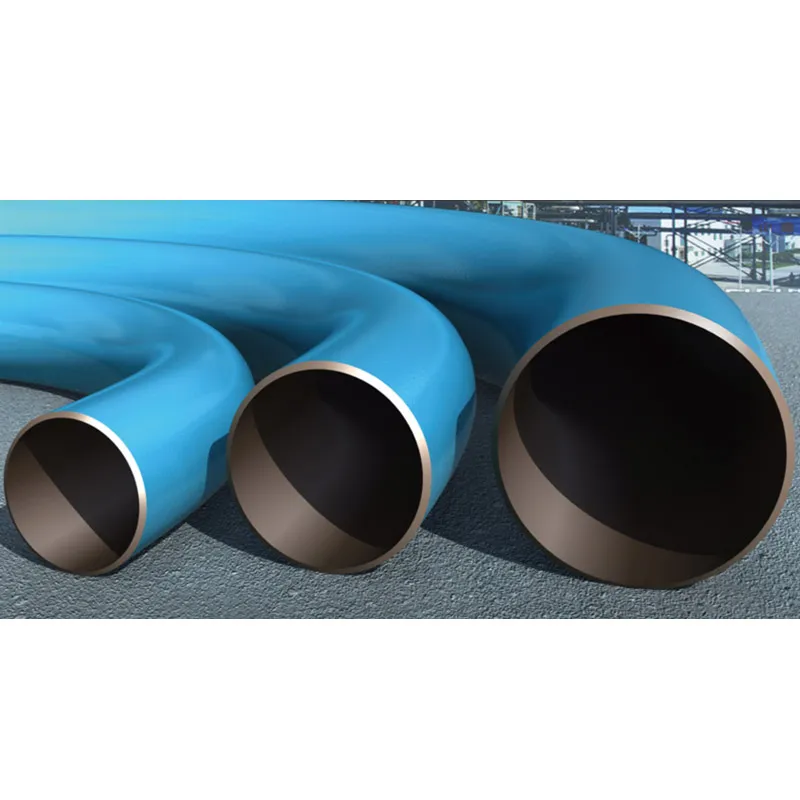

(steel pipe factory)

Our steel pipe factory leverages robotic welding arms with 0.02mm precision - 3X tighter than industry standards. See how our specs dominate:

| Feature | Our Factory | Industry Average |

|---|---|---|

| Wall Thickness Tolerance | ±0.1mm | ±0.3mm |

| Surface Finish | Ra ≤ 3.2μm | Ra ≤ 6.3μm |

While other pipe fittings factories cut corners, we invest in what matters:

Need carbon steel reducers for extreme temperatures? Our engineers developed a proprietary quenching process that enhances durability at 800°C+ environments. Last month alone, we customized:

2,500+ API 5L X65 pipes with 3-layer FBE coating

Custom 90° elbows for 12" SCH160 pipelines

When a Texas oil giant needed 18,000 metric tons of carbon steel reducers in 8 weeks...

"They delivered in 6 weeks with zero defect - saving us $2.8M in downtime costs."

Join 1,200+ satisfied clients who boosted project ROI by 18-35%.

Every second counts - response guaranteed in 4 business hours

(steel pipe factory)

A: Our steel pipe factory manufactures seamless, welded, and galvanized steel pipes in various sizes and grades. These products are suitable for industrial, construction, and plumbing applications. Custom specifications are available upon request.

A: Our pipe fittings factory adheres to international standards (e.g., ASTM, ANSI) for dimensions and threading. We provide detailed technical specifications and material certifications to guarantee compatibility. Custom fittings can also be engineered for unique requirements.

A: Carbon steel reducers from our factory provide high strength, corrosion resistance, and durability under extreme pressure. They are ideal for connecting pipes of different diameters in oil, gas, and chemical industries. Heat treatment options enhance performance for specific environments.

A: Yes, our steel pipe factory operates advanced production lines and maintains large inventory stocks for rapid fulfillment. We offer flexible scheduling and expedited shipping options. Bulk order discounts are available for long-term partnerships.

A: Our carbon steel reducer factory conducts ultrasonic testing, hydrostatic pressure checks, and material composition analysis. All products undergo rigorous inspection per ISO 9001 standards. Traceability documentation is provided for every batch.

A Deep Dive into Flanges: Key Components for Connection and Sealing

A Comprehensive Guide to Varied Flange Types and Their Applications

The Crucial Role of Flanges in Industrial and Utility Systems

Flange Varieties in Industrial Applications: A Comprehensive Overview

Flange Solutions for Enhanced Plumbing and Fixture Installations

Exploring the Diverse World of Flanges and Their Critical Roles

A Deep Dive into Flanges: Key Components for Connection and Sealing

A Comprehensive Guide to Varied Flange Types and Their Applications

The Crucial Role of Flanges in Industrial and Utility Systems

Flange Varieties in Industrial Applications: A Comprehensive Overview

弊社の製品にご興味がございましたら、こちらに情報を残していただければ、すぐにご連絡させていただきます。