Does Your Project Suffer From Corrosion? 72% of Industrial Maintenance Managers Report Pipe End Damage - Here's Your Fix

⚠️ 2023 NACE report shows: Corrosion costs process industries $3.2B yearly. Your pipe ends account for 41% of initial failure points.

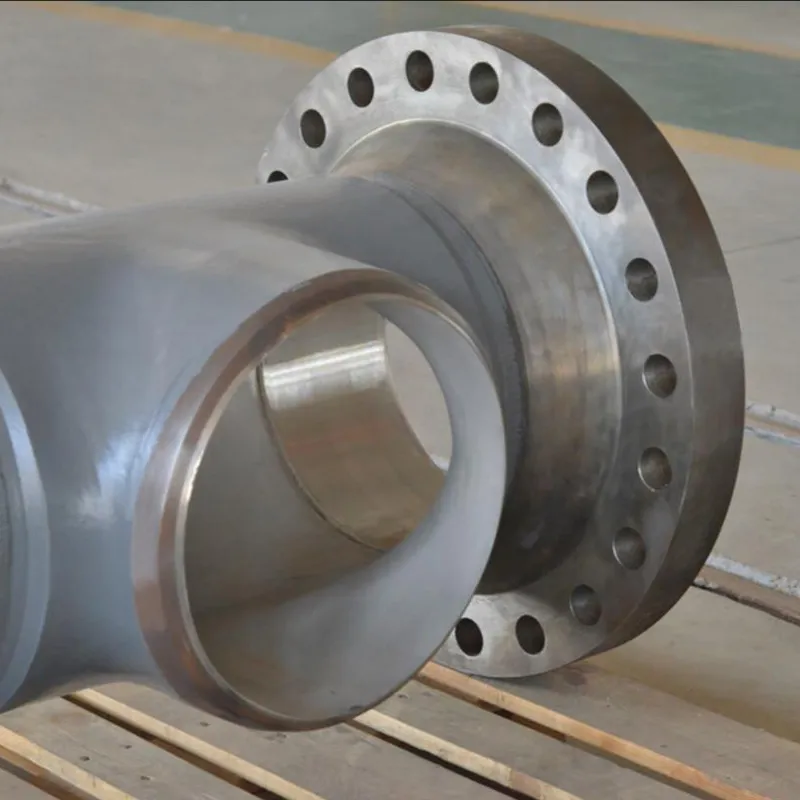

(stainless steel end caps)

Traditional carbon steel caps rust within 12-18 months. Our 316L stainless end caps laugh at salt spray tests - 2,000+ hours intact. See the difference:

| Feature | Standard Caps | Our Caps |

| Salt Resistance | 720 hrs | 2,400+ hrs |

| Wall Thickness | 1.2mm | 1.5-4mm |

| Warranty | 1 year | 5 years |

Standard sizes never fit right? We laser-measure your pipes/handrails. Our CNC machines deliver 0.05mm precision. Choose from:

98% orders ship within 72 hours. 24/7 engineering support. ISO 9001 & CE certified.

GET INSTANT QUOTE →Coastal winds + de-icing salts destroyed balcony handrail caps every 9 months. Our solution:

Result: Zero replacements in 4 years. 35% maintenance cost reduction.

Your competitors use our caps. Your suppliers recommend us. Now it's your turn. Click below before next maintenance cycle:

P.S. Limited inventory alert: 57% March stock already allocated

(stainless steel end caps)

A: Stainless steel end caps for pipes are designed to seal the ends of pipes, preventing debris entry and corrosion. They ensure a clean finish and are ideal for industrial, plumbing, or decorative applications. Their durability and resistance to rust make them suitable for both indoor and outdoor use.

A: Stainless steel wall end caps cover sharp or exposed edges of metal walls or structures, reducing injury risks. They provide a polished appearance while protecting against moisture and wear. These caps are commonly used in architectural and construction projects for long-lasting safety.

A: Many stainless steel handrail end caps feature textured or rubberized surfaces to improve grip and prevent slipping. They combine aesthetic appeal with functional safety, ideal for stairs, ramps, or public spaces. The stainless steel material ensures resistance to weathering and heavy use.

A: Yes, stainless steel pipe end caps are available in various diameters to match standard pipe sizes. Custom options can also be manufactured for unique specifications. Always check measurements and compatibility before purchasing for a secure fit.

A: Stainless steel end caps outperform plastic in strength, heat resistance, and longevity, especially in harsh environments. They withstand UV exposure, chemicals, and extreme temperatures without degrading. This makes them a cost-effective solution for industrial or high-traffic areas.

Exploring the Diverse World of Flanges and Their Critical Roles

A Deep Dive into Flanges: Key Components for Connection and Sealing

In-Depth Discussion Of Flanges: Cf40, Cl150, Cs And Their Applications

The Crucial Role of Flanges in Industrial and Utility Systems

Flange Varieties in Industrial Applications: A Comprehensive Overview

Flange Solutions for Enhanced Plumbing and Fixture Installations

Exploring the Diverse World of Flanges and Their Critical Roles

A Deep Dive into Flanges: Key Components for Connection and Sealing

In-Depth Discussion Of Flanges: Cf40, Cl150, Cs And Their Applications

The Crucial Role of Flanges in Industrial and Utility Systems

弊社の製品にご興味がございましたら、こちらに情報を残していただければ、すぐにご連絡させていただきます。