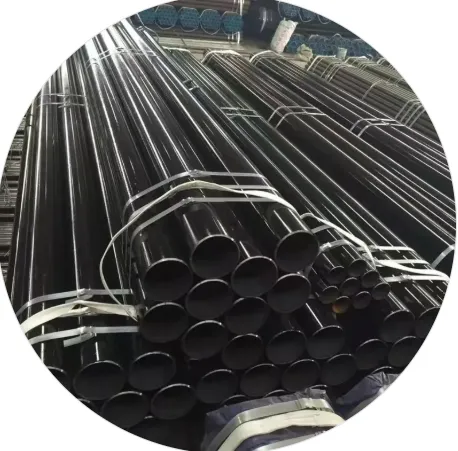

In the realm of industrial piping solutions, Cangzhou Lion Technology Co., Ltd. stands as a leading provider of high-quality carbon seamless steel pipes. A cornerstone of our manufacturing excellence is the cold drawing process, which elevates the precision, durability, and performance of our seamless carbon steel pipes. This article delves into the intricacies of our cold drawing techniques, highlighting how they contribute to the superior quality of our products and meet the demanding requirements of diverse industrial applications.

The Significance of Cold Drawing in Carbon Seamless Steel Pipes Production

The cold drawing process is fundamental to the production of carbon seamless steel pipes at Cangzhou Lion Technology Co., Ltd. Unlike hot working, cold drawing enhances the mechanical properties of steel by deforming the material at room temperature, resulting in improved tensile strength, yield strength, and surface finish. This process is crucial for creating seamless carbon steel pipe products that meet strict industry standards for precision and reliability, making them ideal for high-pressure and high-stress applications.

How Cold Drawing Enhances the Precision of Seamless Carbon Steel Pipe

Cangzhou Lion Technology Co., Ltd.’s cold drawing process significantly enhances the precision of seamless carbon steel pipe. By pulling the heated steel billet through a die, we achieve tight dimensional tolerances in both outer diameter and wall thickness. This precision ensures that our seamless carbon steel tube products fit seamlessly into complex piping systems, reducing installation challenges and minimizing the risk of leaks or failures. The process also results in a smooth inner and outer surface, optimizing fluid flow and reducing friction.

|

標準

|

API、ASTM、API 5L、ASTM A106、ASTM A53

|

|

厚さ

|

2 – 60 mm

|

|

外径

|

21.3 – 1828mm

|

|

応用

|

流体輸送

|

|

認証

|

API

|

|

特殊パイプ

|

API パイプ

|

|

材料

|

API 5L GR A GR B、GR C、ASTM A 53、ASTM A 106

|

|

形

|

ラウンド

|

|

終了

|

体育

|

|

表面

|

黒塗装

|

|

パッケージ

|

輸出梱包基準

|

|

長さ

|

5.8m-12m

|

|

最小注文数量

|

5トン

|

|

原産地

|

中国、滄州

|

|

技術

|

熱間圧延または冷間引抜

|

|

合金か否か

|

非合金

|

|

タイプ

|

シームレス鋼管

|

|

エンドプロテクター

|

カスタマイズ

|

|

支払方法

|

TT/LC

|

Key Features of Cold-Drawn Seamless Carbon Steel Tube

Our cold-drawn seamless carbon steel tube offer several distinct features:

- Enhanced Mechanical Properties: Cold drawing improves the steel’s strength and hardness without compromising ductility.

- Superior Surface Finish: The process yields a smooth, burr-free surface that reduces corrosion risks and enhances aesthetic appeal.

- Tight Dimensional Control: Consistent wall thickness and diameter ensure compatibility with standard fittings and connectors.

- Versatile Application: Suitable for various industries, including oil and gas, construction, and mechanical engineering.

|

標準

|

JIS ,DIN, BS EN10024, API 5L,API 5CT, ASTM A106, ASTM A53, ANSI B36.10M, DIN EN 10217, DIN 17175

|

|

材料

|

A53(A,B)、A106(B,C)、ST37、ST52、St37-2、St42-2、STB35、STB42、Q235、Q345、Q195、16分、20#、45#

|

|

厚さ

|

2mm – 75mm

|

|

断面形状

|

ラウンド

|

|

の

|

12mm – 1000mm

|

|

原産地

|

中国

|

|

技術

|

熱間圧延、冷間引抜

|

|

認証

|

API

|

|

表面処理

|

黒塗り

|

|

特殊パイプ

|

厚肉パイプ

|

|

合金か否か

|

非合金

|

|

許容範囲

|

±10%

|

|

タイプ

|

シームレス鋼管

|

|

エンドプロテクター

|

プラスチックパイプキャップ

|

|

パッケージ

|

輸出梱包基準

|

|

サービス

|

カスタマイズOEM

|

|

長さ

|

5.8m-12m

|

|

最小注文数量

|

5トン

|

Cangzhou Lion Technology Co., Ltd.’s Advanced Cold Drawing Process for 炭素シームレス鋼管

As a leading wholesaler, we employ a meticulous cold drawing process for carbon seamless steel pipes:

- Billet Preparation: High-quality carbon steel billets are inspected and pre-treated to remove impurities.

- Piercing: The billet is pierced to form a hollow shell, creating the base for the seamless pipe.

- Cold Drawing: The shell is drawn through dies to reduce diameter and wall thickness, achieving precise dimensions.

- Heat Treatment: Post-drawing heat treatment restores ductility and relieves internal stresses.

- Quality Inspection: Each pipe undergoes rigorous testing for dimensional accuracy, mechanical properties, and surface finish.

Seamless Carbon Steel Pipe FAQS

Why is cold drawing important for carbon seamless steel pipes?

Cold drawing is vital for carbon seamless steel pipes as it enhances mechanical properties and precision. Cangzhou Lion Technology Co., Ltd.’s cold drawing process improves tensile strength and surface finish, ensuring our seamless carbon steel pipe products meet high-pressure application requirements while reducing installation complexities.

How does cold drawing affect the durability of seamless carbon steel pipe?

Cold drawing strengthens the steel structure of seamless carbon steel pipe, making it more resistant to wear, corrosion, and mechanical stress. The process eliminates internal defects and ensures uniform material density, extending the pipe’s service life in harsh industrial environments.

What industries benefit most from cold-drawn seamless carbon steel tube?

Seamless carbon steel tube from our cold drawing process are ideal for industries like oil and gas, petrochemicals, and construction. Their precision and durability make them suitable for high-pressure pipelines, structural supports, and mechanical components requiring reliable performance.

How do we ensure quality in carbon seamless steel pipes?

We ensure quality by subjecting carbon seamless steel pipes to rigorous testing, including ultrasonic flaw detection, hydrostatic pressure tests, and tensile strength analysis. This ensures each product meets international standards for dimensional accuracy and mechanical performance.

How does the company ensure safe international shipping of seamless carbon steel pipes?

For international shipping, Cangzhou Lion Technology Co., Ltd. uses specialized packaging to protect carbon seamless steel pipes from damage. We partner with reliable carriers and provide ocean bills of lading for customs clearance, ensuring products arrive in optimal condition for immediate use.