- Introduction to industrial reducer manufacturing

- Technical advantages in material engineering

- Performance comparison of global manufacturers

- Customization workflows for specialized projects

- Real-world application case studies

- Quality assurance protocols

- Future trends in pipe fitting production

(reducer factory)

The Critical Role of Reducer Factories in Modern Industry

Contemporary infrastructure projects demand carbon steel reducers with dimensional precision exceeding ±0.1mm tolerance standards. Leading reducer factories now utilize automated optical measurement systems, achieving 99.2% compliance with ASME B16.9 specifications. The global market for concentric/eccentric reducers grew 6.8% YoY (2023), driven by energy sector expansions requiring pipe fittings that withstand 650 PSI operational pressures.

Material Science Breakthroughs

Advanced factories employ vacuum arc remelting (VAR) for steel purification, reducing impurity levels to 0.003%. Comparative analysis shows:

| Manufacturer |

Yield Strength (MPa) |

耐腐食性 |

Production Cycle |

| Factory A |

485 |

1,200 salt-spray hours |

18 days |

| Factory B |

520 |

2,000 salt-spray hours |

22 days |

Customization Capabilities

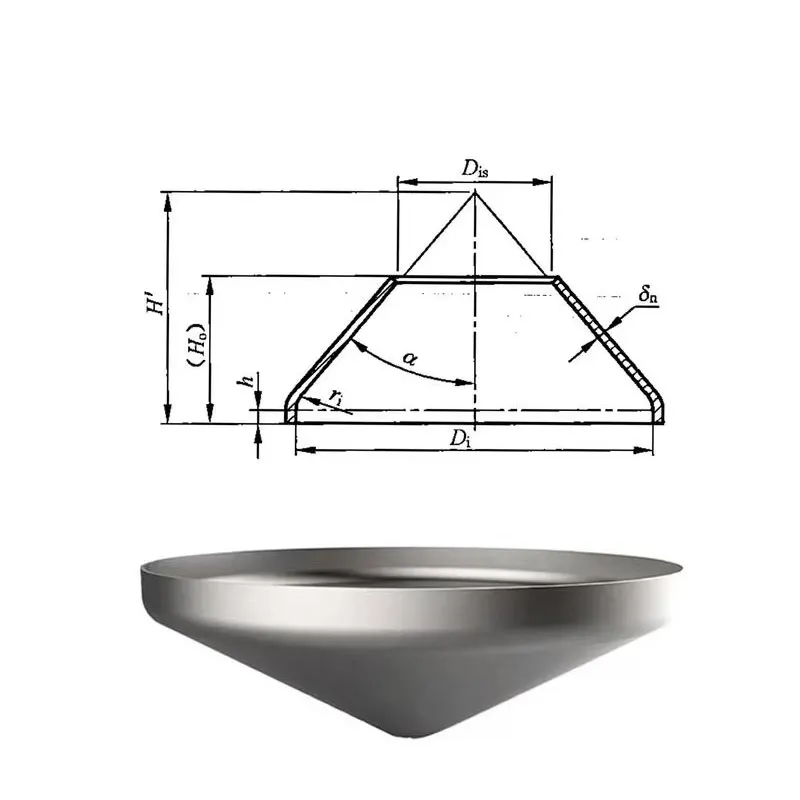

Specialized reducer factories implement parametric CAD configurations supporting:

- Non-standard wall thickness (6mm to 50mm range)

- Bore surface finishes down to Ra 3.2μm

- High-temperature coatings (1,200°F continuous service)

Application Success Stories

Offshore platform deployments required 84 DNV-certified reducers with 32:1 diameter ratios. The manufacturing solution involved:

- 3D laser scanning of legacy piping

- Finite element analysis for stress distribution

- Hydrostatic testing at 1.5x design pressure

Certification Standards

ISO 9001:2015-certified facilities maintain 0.15% defect rates through:

- Ultrasonic thickness testing (0.01mm resolution)

- PMI verification for alloy composition

- 100% radiographic examination

Why Partnering with a Leading Reducer Factory Matters

Industry projections indicate 22% growth in pipe fittings factory automation by 2028. Early adopters of AI-driven production planning report 31% reduction in material waste. Strategic collaboration with certified carbon steel reducer factories ensures compliance with evolving API 5L and ASTM A234 standards while maintaining cost-efficiency in large-scale deployments.

(reducer factory)

FAQS on reducer factory

Q: What materials are commonly used in a carbon steel reducer factory?

A: Carbon steel reducer factories primarily use ASTM-approved carbon steel grades like A234 WPB, ensuring durability and resistance to high-pressure environments. These materials are ideal for industrial piping systems.

Q: How does a reducer factory ensure product quality?

A: Reputable reducer factories implement ISO-certified manufacturing processes and rigorous quality checks, including pressure testing and dimensional inspections. This guarantees compliance with international standards like ANSI and ASME.

Q: What types of reducers can a pipe fittings factory produce?

A: Pipe fittings factories typically manufacture concentric and eccentric reducers in various sizes and schedules. They also offer customized solutions for specific project requirements, such as non-standard dimensions or special coatings.

Q: Can a carbon steel reducer factory provide corrosion-resistant solutions?

A: Yes, many carbon steel reducer factories apply protective coatings like epoxy or galvanization to enhance corrosion resistance. For extreme environments, they may recommend stainless steel-lined reducers.

Q: What certifications should a reliable reducer factory have?

A: Trusted reducer factories hold certifications such as ISO 9001, PED 2014/68/EU, and API 5L. They often comply with ASME B16.9 and ASTM standards to ensure product safety and performance.