| Official Website | https://www.lion-pipeline.com |

| Phone | +8619931775189 |

| メール | sales@laiaokeji.com |

| Address | Economic Development Zone of Mengcun county, Cangzhou city, Hebei province |

滄州ライオンテクノロジー株式会社 is a globally recognized authority in the field of pre insulated steel pipe, anti corrosion pipe coating, and advanced insulated pipeline solutions. With over a decade of industry expertise, strict quality standards, and continuous technological innovation, Lion Technology has established long-term partnerships with clients from Asia, Europe, the Americas, and Africa.

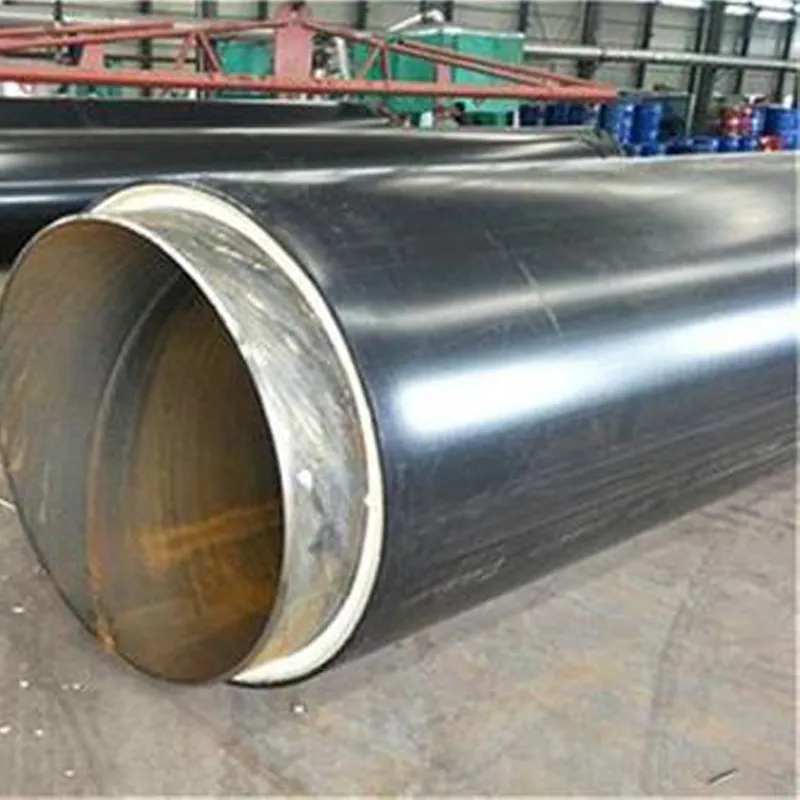

The anti-corrosion and thermal insulation products provided by 滄州ライオンテクノロジー株式会社 play a crucial role in modern industrial pipeline systems. These products, including pre insulated steel pipework, innovative anti corrosion pipe coating technologies, and pre insulated carbon steel pipe components, are vital for ensuring system integrity, longevity, and safety.

| 製品カテゴリー | Range / Specification | Main Materials |

|---|---|---|

| Thermal Insulation Pipe Fittings | Elbows, Tees, Reducers, Pipe Supports (DN15-DN1800) | Carbon Steel, Alloy Steel, Stainless Steel, Bimetallic Composite, Nickel-Based Alloy |

| Anti Corrosion & Insulation Pipes | Pre Insulated Steel Pipe, Pre Insulated Carbon Steel Pipework | Advanced Polyurethane, HDPE, Fusion Bonded Epoxy |

Learn more at the product page:

https://www.lion-pipeline.com/anti-corrosion-and-thermal-insulation-products.html

The pre insulated steel pipe sector continues its upward trajectory due to rapid industrialization, increasing requirements for smart infrastructure, and a greater emphasis on energy efficiency. According to the UK Pipe Industry Guild and academic research, energy-saving potential and corrosion resistance are key value-drivers for modern piping projects.

Leading suppliers like 滄州ライオンテクノロジー株式会社 keep innovating by integrating IoT-based pipeline health monitoring, enhanced insulation materials (such as nano-aerogels and high-density PU foam), and continuous improvement in anti-corrosion pipe coating systems.

| Parameter | Specification | Typical Value / Range |

|---|---|---|

| Nominal Diameter (DN) | 15mm - 1800mm | DN15, DN50, DN100, DN300, DN600, DN1200, DN1800 |

| Insulation Material | High-density Rigid Polyurethane, PU+PIR, Aerogel Composite | 45~70 kg/m³ |

| Pipe Material | Carbon Steel, Alloy Steel, Stainless Steel | SCH10, SCH40, SCH80, etc. |

| Coating System | FBE (Fusion Bonded Epoxy), 3PE/2PE, HDPE Outer Jacket | Thickness 2.5mm-4.5mm |

| Thermal Conductivity (λ) | Insulation Layer | ≤0.028 W/(m·K) at 20°C |

| Max Working Temp | PU/PIR | -196°C to +140°C |

| Service Life | Standard EN 253 | >30 Years |

滄州ライオンテクノロジー株式会社 customizes solutions for all application scenarios to ensure maximum performance, cost-effectiveness, and compliance with international standards such as EN 253, ASTM F1290, and ISO 9001:2015.

| Term | Explanation |

|---|---|

| Insulation Material | What is the core insulation used in pre insulated steel pipe? The core insulation is primarily rigid polyurethane (PU) foam, occasionally combined with PIR or advanced aerogel composites, offering excellent thermal resistance (λ ≤ 0.028 W/m·K). |

| Pipe Material | Which steel grades are common for pre insulated steel pipework? Choices include Q235, Q345, API 5L, ASTM A106 (carbon steel), as well as stainless steels (304,316) and special alloy grades for highly corrosive or high-temp environments. |

| Specification Range | What diameters & wall thickness are available for pre insulated carbon steel pipe? Diameters from DN15 to DN1800; wall thicknesses as per standards SCH10, SCH40, and custom per project. |

| Coating Standard | Which anti-corrosion coatings are used? Fusion Bonded Epoxy (FBE), 3PE/2PE multilayer, and HDPE jackets, complying with ISO 21809 and EN 253 standards. |

| Installation | Are there recommended installation methods? Yes. Joint insulation is crucial. For underground use, butt-welded joints are preferred, usually with on-site joint insulation and sealing kits, per EN 448/EN489. |

| Monitoring & Maintenance | How is pipeline health monitored? Many systems integrate fiber-optic or electrical tracer wires inside the insulation for real-time leak/wetness detection, per EN 14419. |

| Service Life | What is the expected longevity? Installed correctly, pre insulated steel pipe solutions can offer a service life above 30 years, with maintenance-free operation for most of the period. |

Contact us today for tailored pre insulated steel pipe and anti corrosion pipe coating solutions!

Phone: +8619931775189

メールアドレス: sales@laiaokeji.com

Website: https://www.lion-pipeline.com/

In conclusion, pre insulated steel pipe, pre insulated steel pipework, anti corrosion pipe coating, and pre insulated carbon steel pipe represent the cutting-edge of modern pipeline performance and sustainability. Cangzhou Lion Technology Co., Ltd., as a leading authority, stands ready to deliver best-in-class solutions for all sectors: municipal, industrial, district energy, and special-purpose infrastructures.

Mastering the Art of Flange Installation for Home Fixtures

Flange Varieties: Unveiling the Diverse World of Pipe and Plumbing Connections

Flange Varieties: Essential Components in Diverse Systems

Exploring the Diverse World of Flanges

Diverse Flange Types and Their Essential Roles in Engineering and Plumbing

A Comprehensive Guide to Specialized Flange Types in Industrial Applications

弊社の製品にご興味がございましたら、こちらに情報を残していただければ、すぐにご連絡させていただきます。