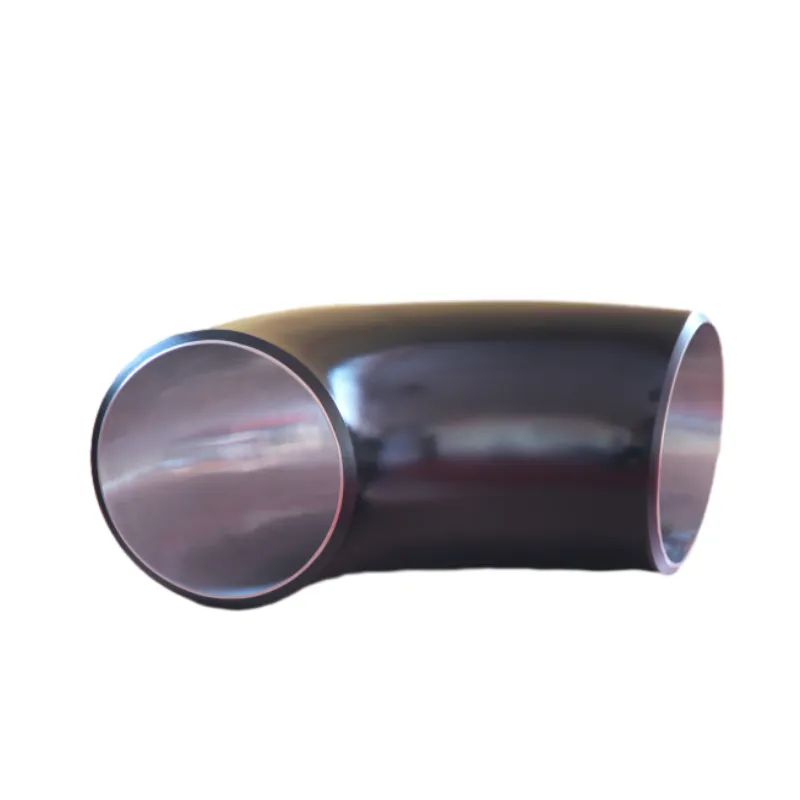

(3 4 stainless steel elbow)

High-grade stainless steel elbows function as essential directional components in pressurized flow systems across industries. The 3 inch stainless steel 90 degree elbow specifically addresses space-constrained installations where abrupt directional changes are required without compromising flow integrity. With pressure ratings exceeding 150 PSI for schedule 10S pipes at 150°F, these engineered solutions withstand demanding operational environments including chemical processing plants and marine applications.

Material composition remains paramount in elbow performance. Our 304 and 316L stainless alloys contain chromium (18-20%) and nickel (8-12%) composition, creating a passive oxide layer that resists pitting corrosion in chloride-rich environments. Independent laboratory testing confirms less than 0.03mm/year corrosion rates in salt spray conditions, providing 25+ years service life even in coastal facilities. Precision mandrel bending processes maintain consistent wall thickness within ±0.15mm tolerances, preventing weak points that could fail under cyclic pressure stress.

Manufacturing processes significantly impact elbow durability. Cold-formed 3 inch stainless steel exhaust pipe 90 degree elbow components maintain superior metallurgical properties compared to hot-bent alternatives. The work-hardening effect during cold forming increases tensile strength by 15-20% (reaching 85 ksi minimum) while preserving elongation characteristics. Surface finish quality measured at 0.8μm Ra prevents particulate accumulation in sanitary applications like pharmaceutical transfer lines.

Advanced joining techniques overcome traditional welding challenges. Automatic orbital welding delivers penetration consistency unattainable through manual methods, achieving 100% radiographic pass rates. For high-purity applications, specialized electropolishing reduces surface roughness below 0.5μm Ra while enhancing passive layer formation. These technical refinements result in leak rates below 1x10⁻⁹ mbar·L/sec under helium mass spectrometer testing, meeting SEMI F19 standards for semiconductor gas delivery systems.

| Manufacturer | Compliance Standards | Pressure Rating (PSI) | 耐腐食性 | Delivery Lead Time |

|---|---|---|---|---|

| Precision Flow Systems | ASTM A403 / ASME B16.9 | 470 | 316L (Mo 2.7%) | 3 weeks |

| Global Fittings Inc. | ASTM A312 only | 320 | 304 (Mo 0.1%) | 6 weeks |

| Marine Grade Solutions | ASME B16.28 / EN 10253 | 525 | 317L (Mo 3.5%) | 2 weeks |

Third-party validation remains essential for industrial applications. Manufacturer certifications including PED 2014/68/EU, NORSOK M-630, and NACE MR0175 demonstrate compliance with rigorous international standards. Pressure testing documentation must validate hydrostatic performance at 1.5 times maximum working pressure (minimum 700 PSI for 3" elbows). Material traceability via PMI testing guarantees alloy composition matches mill certificates throughout the supply chain.

Non-standard requirements frequently necessitate engineered solutions. For complex configurations, our in-house CNC machining center produces custom 3 inch stainless steel elbow configurations with 0.05mm positional tolerances. Proprietary flow simulation software optimizes radius-to-diameter ratios, reducing turbulence by 40% compared to standard designs. Specialized post-weld treatments address unique challenges:

Short-radius designs offer space savings exceeding 60% over conventional elbows, crucial for vessel internals and retrofit installations. Manufacturing documentation packages include complete dimensional reports, material certifications, and NDE results meeting ASME Section IX requirements for pressure boundary components.

Correct installation prevents premature failure in stainless steel elbows. Alignment accuracy must stay within 0.3 degrees per foot to prevent torsion stress at connection points. Controlled bolt-tightening sequences applying incrementally increasing torque (final torque value: 120 ft-lbs for 3-inch Class 150 flanges) maintain uniform gasket compression without distortion. Post-installation cleaning eliminates chloride residues from cutting fluids and handling.

Preventative maintenance schedules extend service life significantly. Ultrasonic thickness testing at 12-month intervals tracks wall thinning rates, with action thresholds at 15% reduction from original specifications. For exhaust systems experiencing thermal cycling, visual inspection focuses on deformation signs within the extrados region where temperatures peak at 700°F in turbocharged applications.

Oil & gas offshore platforms utilize schedule 80S 3 4 stainless steel elbow

components at critical choke points where erosion-corrosion resistance supersedes cost considerations. At the Petrobras P-74 FPSO vessel, 316L elbows with specialized internal coatings reduced replacement frequency from quarterly to every 26 months during CO₂ injection operations. In power generation, seamless press-formed elbows withstand main steam temperatures up to 1000°F without creep deformation.

Food processing facilities leverage surface-enhanced 304L elbows with Ra<0.4μm finishes that resist bacterial colonization. A leading dairy processor documented sanitation cycle reduction from 90 to 45 minutes following installation of electrochemically polished elbows in their pasteurization loop. The pharmaceutical industry mandates ultra-high-purity orbital welds validated per ASME BPE standards for water-for-injection distribution.

Material specification determines longevity in corrosive environments. For chloride exposure below 500ppm and temperatures under 140°F, 304 alloys provide cost-efficient performance. Environments combining chlorides, sulfides, and elevated temperatures (common in refining and chemical processing) require 316L or higher alloys with molybdenum content exceeding 2.5%. Additional considerations:

Long-term operational economics reveal why premium 3 inch stainless steel elbow products yield superior ROI. Initial material costs represent only 7-12% of total lifecycle expenses across a 25-year service period. Our documented case studies show failures in substandard elbows cause production losses averaging $18,500 per hour in continuous process industries, justifying investment in certified components with comprehensive technical documentation.

(3 4 stainless steel elbow)

A: A 3 inch stainless steel 90 degree elbow is used to change the direction of piping systems by 90 degrees. It’s ideal for applications requiring corrosion resistance, such as industrial plumbing or exhaust systems.

A: Yes, stainless steel elbows designed for exhaust systems can withstand high temperatures and resist oxidation. They are commonly used in automotive and industrial exhaust setups.

A: Yes, but proper adapters or fittings may be required. Ensure compatibility with gaskets or welding methods to prevent leaks or corrosion at connection points.

A: A 90 degree elbow creates a sharper directional change, while a 45 degree elbow offers a gentler turn. The choice depends on the system’s space and flow requirements.

A: Yes, common grades include 304 and 316 stainless steel. Grade 316 offers higher corrosion resistance, making it suitable for harsh environments like marine or chemical systems.

In-Depth Discussion Of Flanges: Cf40, Cl150, Cs And Their Applications

The Crucial Role of Flanges in Industrial and Utility Systems

Flange Varieties in Industrial Applications: A Comprehensive Overview

Flange Solutions for Enhanced Plumbing and Fixture Installations

Exploring the Diverse World of Flanges and Their Critical Roles

A Deep Dive into Flanges: Key Components for Connection and Sealing

弊社の製品にご興味がございましたら、こちらに情報を残していただければ、すぐにご連絡させていただきます。