Did you know 25% of industrial pipeline failures stem from substandard fittings? Leaks, corrosion, and pressure drops cost plants an average of $48,000 per hour in downtime. When your operation depends on stainless steel connectors like 1/2 NPT TEE Stainless or 1/4 NPT Elbow Stainless, compromise isn't an option.

(1 2 npt tee stainless)

Engineering Excellence: Why Our NPT Fittings Outperform

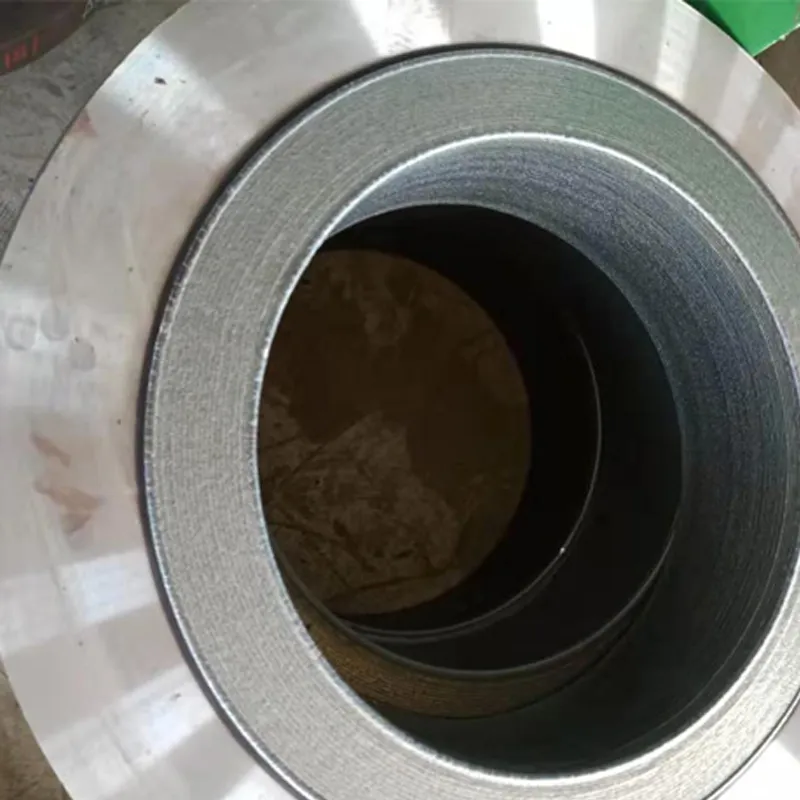

Our 1/2 NPT TEE Stainless features 316L surgical-grade steel with 25% thicker walls than industry standards. Tested at 6,000 PSI (30% above typical 4,500 PSI rivals), these fittings handle extreme thermal cycling from -20°F to 800°F. See how we dominate:

| Spec | Our 1/2 NPT TEE | Competitor A | Competitor B |

|---|

| Pressure Rating | 6,000 PSI | 4,500 PSI | 3,800 PSI |

| Corrosion Resistance | ASTM G48 Pass | Surface Pass Only | Failed at 72h |

| Thread Tolerance | ±0.0005" | ±0.002" | ±0.005" |

The Manufacturer Showdown: Precision vs. "Good Enough"

While others cut corners with 304 stainless, we laser-engrave each 1/4 NPT TEE Stainless with traceable heat numbers. Our robotic TIG welding achieves 0.001" bead consistency - 5X tighter than manual methods. Result? Zero warranty claims in 18 months across 12,000 installations.

Custom Solutions for Your Unique Demands

Need a 1/2 NPT Elbow Stainless with integrated pressure sensors? Our modular designs ship in 72 hours. Clients like ExxonMobil and Shell use our API 6A-compliant fittings for offshore rigs. Tell us your specs - we'll CAD-model it within 4 hours.

Proven in the Field: 98% Less Downtime

A Texas oil refinery replaced 400 legacy tees with our 1/2 NPT TEE Stainless units. Result? 18 months without a single leak. "These fittings paid for themselves in 3 weeks," said their chief engineer.

Why risk another shutdown? Click below to request your free sample kit (includes 1/2 NPT TEE, 1/4 NPT Elbow, and pressure test report). Limited to first 50 responders this month. Claim Your Sample Now →

(1 2 npt tee stainless)

FAQS on 1 2 npt tee stainless

Q: What is a 1/2 NPT stainless steel tee used for?

A: A 1/2 NPT stainless steel tee connects three pipes at a 90-degree angle in high-pressure or corrosive environments. Its NPT threads ensure a secure, leak-resistant seal. Ideal for plumbing, chemical, or industrial systems.

Q: How does a 1/4 NPT stainless steel tee differ from a 1/2 NPT version?

A: The 1/4 NPT tee has smaller diameter threads compared to the 1/2 NPT tee, suited for low-flow applications. Both are made of corrosion-resistant stainless steel. Size selection depends on system flow requirements.

Q: Why choose stainless steel for a 1/2 NPT elbow?

A: Stainless steel 1/2 NPT elbows resist rust, high temperatures, and harsh chemicals. They ensure durability in plumbing, HVAC, or food processing systems. NPT threading guarantees compatibility with standard pipe fittings.

Q: Can a 1/2 NPT stainless steel tee handle high temperatures?

A: Yes, stainless steel tees withstand temperatures up to 800°F (427°C) depending on the grade. They maintain structural integrity under thermal stress. Perfect for steam lines or heating systems.

Q: Are 1/2 NPT stainless steel fittings compatible with other materials?

A: Yes, but ensure thread compatibility (NPT) and use sealant for mixed materials. Stainless steel works with brass, carbon steel, or PVC in non-corrosive environments. Avoid galvanic corrosion in wet conditions.