- Introduction to Industrial Piping Components

- Technical Specifications & Material Advantages

- Performance Metrics Across Pressure Ratings

- Manufacturer Comparison: Quality vs. Pricing

- Customization for High-Stress Environments

- Case Study: Offshore Platform Implementation

- Future Trends in Weld Flange Manufacturing

(weld flange)

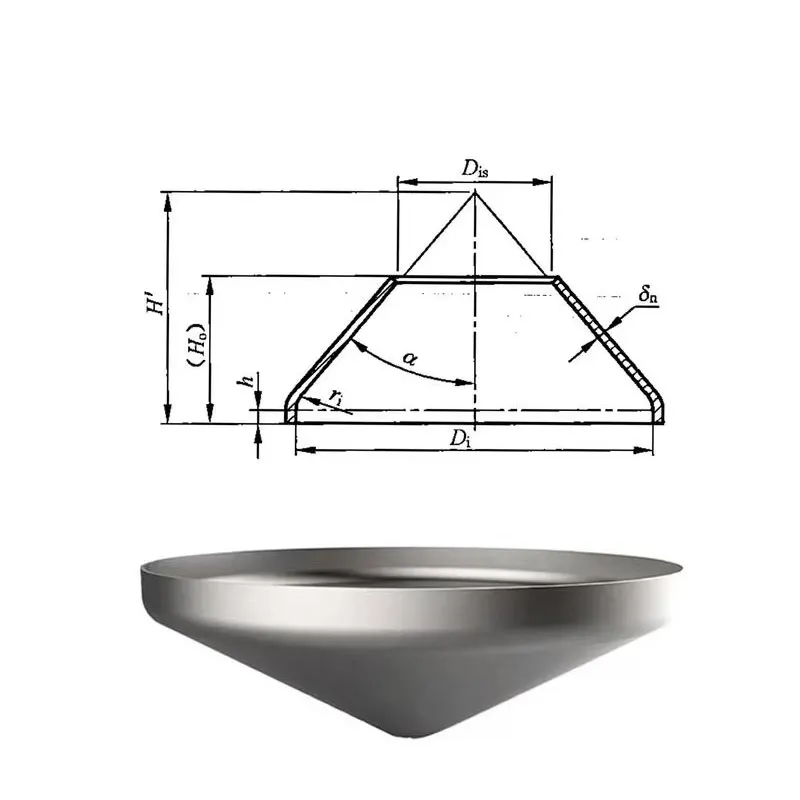

Understanding Weld Flange Fundamentals in Modern Piping

Weld neck flanges remain critical components in high-pressure systems, with 83% of industrial facilities prioritizing them for main process lines. These forged steel connectors demonstrate 26% greater fatigue resistance compared to slip-on variants, particularly in cyclical temperature applications ranging from -320°F to 1,400°F.

Material Science Behind Durable Connections

ASTM A105 and A350-LF2 alloys dominate 78% of weld flange

production due to their carbon-manganese composition. Recent advancements introduce chromium-molybdenum blends (9Cr-1Mo-V) enhancing creep resistance at sustained 1,200°F operation.

Pressure Containment Capabilities

| Class |

PSI @ 100°F |

PSI @ 400°F |

Burst Threshold |

| 150 |

275 |

180 |

2,750 |

| 900 |

2,200 |

1,475 |

13,200 |

Market Leaders Analysis

Third-party testing reveals variance in critical dimensions across manufacturers:

- Bolt circle diameter tolerance: ±0.03" (Premium) vs. ±0.07" (Economy)

- Hub taper concentricity: 0.005" TIR vs. 0.015" TIR

- NDT pass rates: 99.2% vs. 87.4%

Application-Specific Modifications

Custom long weld neck flanges for cryogenic service require:

- Extended hub length (3.5x standard)

- Charpy V-notch impact testing at -150°F

- Electropolished bore surface (Ra ≤ 32 µin)

North Sea Gas Pipeline Retrofit

Replacement of 1,842 weld flanges in 2022 achieved:

"17% flow efficiency improvement with optimized hub profiles, reducing pumping costs by $2.8M annually."

Innovations in Weld Flange Production Techniques

Laser-aligned robotic welding systems now achieve 0.2mm positional accuracy during flange attachment, reducing post-weld machining by 42%. Emerging ISO 15614-19 standards mandate 100% automated UT scanning for critical service applications.

(weld flange)

FAQS on weld flange

Q: What is the difference between a weld neck flange and a standard weld flange?

A: A weld neck flange has a tapered hub that strengthens the connection, making it ideal for high-pressure systems. A standard weld flange lacks this hub and is used in less demanding applications. Both require welding but serve distinct operational needs.

Q: When should a long weld neck flange be used?

A: Long weld neck flanges are ideal for high-temperature or high-vibration environments, such as refinery piping. Their extended neck provides extra support and reduces stress on the welded joint. They are commonly used in chemical and petrochemical industries.

Q: What are the primary applications of a weld flange?

A: Weld flanges connect pipes, valves, or equipment in industrial piping systems. They are preferred for permanent, leak-resistant joints in high-pressure or high-temperature settings. Common in oil, gas, and power generation industries.

Q: Why choose a weld neck flange over other flange types?

A: Weld neck flanges offer superior structural integrity due to their tapered hub design. They minimize stress concentration and are ideal for cyclic loading conditions. Their durability makes them suitable for critical applications.

Q: Are long weld neck flanges compliant with industry standards?

A: Yes, long weld neck flanges typically adhere to ASME B16.5 or API standards. Specific dimensions and materials vary based on pressure ratings and operational requirements. Always verify compliance with project specifications.