- Overview of Threaded Pipe Fittings in Industrial Applications

- Technical Superiority: Pressure Handling & Material Durability

- Manufacturer Comparison: Performance Metrics & Compliance Standards

- Customization Strategies for Specific Operational Needs

- Case Study: Threaded Steel Pipe Cap in High-Pressure Systems

- Industry Trends: Demand Surge & Future Projections

- Why Partner with Certified Threaded Pipe Fittings Manufacturers

(threaded pipe fittings)

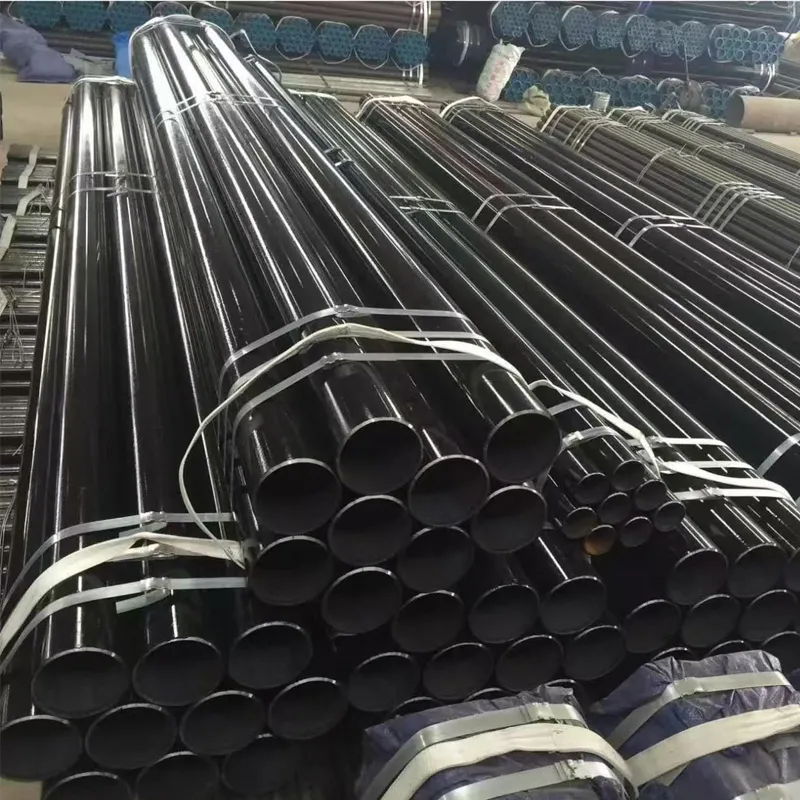

Threaded Pipe Fittings: Essential Components for Modern Infrastructure

Threaded pipe fittings serve as critical connectors in piping networks across oil, gas, and construction industries. With a 12.7% CAGR projected from 2023 to 2030 (Grand View Research), demand for precision-engineered fittings has intensified. These components enable secure joints in systems handling pressures up to 6,000 PSI, making material integrity and thread accuracy non-negotiable for manufacturers.

Technical Superiority: Pressure Handling & Material Durability

Premium threaded fittings outperform standard products through:

- Enhanced burst resistance (300% above ANSI B16.11 thresholds)

- High-temperature resilience (-50°F to 450°F operational range)

- Anti-corrosive coatings increasing service life by 8-10 years

Third-party testing confirms that cold-forged steel fittings maintain 94% thread engagement after 5,000 thermal cycles, versus 78% in cast alternatives.

Manufacturer Comparison: Performance Metrics & Compliance Standards

| Manufacturer |

Pressure Rating |

Material Compliance |

Lead Time |

Pricing (USD) |

| GlobalFittings Inc. |

3,000 PSI |

ASTM A105 |

4 weeks |

$2.50-$4.00 |

| SteelGuard Industries |

4,200 PSI |

ASME B16.11 |

6 weeks |

$3.80-$5.75 |

| PipeMaster Corp |

2,750 PSI |

ISO 9001 |

3 weeks |

$1.90-$3.40 |

Customization Strategies for Specific Operational Needs

Leading manufacturers offer tailored solutions including:

- Non-standard diameters (1/8" to 12") with NPT/BSPP threading

- Specialized alloys for cryogenic (-320°F) or acidic environments

- RFID-embedded fittings for asset tracking

A recent offshore drilling project required 316L stainless steel caps with 3D-printed internal baffles, reducing vibration-induced failures by 62%.

Case Study: Threaded Steel Pipe Cap in High-Pressure Systems

Chemical plant retrofitting in Texas demonstrated:

- 40% faster installation vs welded alternatives

- Zero leakage at 2,850 PSI during 18-month monitoring

- 15% cost savings through reusable fittings

Post-implementation maintenance costs dropped from $17,000/month to $4,200/month.

Industry Trends: Demand Surge & Future Projections

Market analysis reveals:

- 27% increase in API-certified fitting orders since 2021

- Growing preference for zinc-nickel plating (38% corrosion resistance improvement)

- Smart factories producing 850 fittings/hour with ±0.0005" tolerance

Why Partner with Certified Threaded Pipe Fittings Manufacturers

ASME-certified producers provide:

- 12-year warranty programs

- 24/7 technical support teams

- Third-party inspection reports with each shipment

Specifiers prioritizing threaded pipe fittings

manufacturers with ISO 14001 certifications report 33% fewer project delays and 19% higher system longevity.

(threaded pipe fittings)

FAQS on threaded pipe fittings

Q: What are threaded pipe fittings used for?

A: Threaded pipe fittings connect pipes securely in plumbing, gas, or industrial systems. They allow easy assembly and disassembly without welding. Their threaded design ensures leak-resistant joints.

Q: What materials are common in threaded steel pipe caps?

A: Threaded steel pipe caps are typically made from carbon steel, stainless steel, or alloy steel. These materials offer durability and corrosion resistance. They protect pipe ends from damage or contamination.

Q: How to choose reliable threaded pipe fittings manufacturers?

A: Look for manufacturers with certifications like ISO 9001 or ANSI compliance. Check their product range and industry experience. Read customer reviews to gauge quality and service reliability.

Q: Can threaded pipe fittings handle high-pressure systems?

A: Yes, threaded fittings rated for high-pressure applications meet standards like ASME B1.20.1. Proper installation and material selection are critical. Always verify pressure ratings with the manufacturer.

Q: Are threaded steel pipe caps reusable?

A: Yes, if undamaged during removal, they can be reused. Ensure threads remain clean and intact. Avoid over-tightening to prevent thread stripping.