1. Industry Trends for Stainless Steel Pipe Caps

The stainless steel cap market has witnessed significant growth, driven by demand in sectors such as oil & gas, petrochemical, metallurgy, water treatment, and residential infrastructure. Innovations in alloy compositions, fabrication, and international standards compliance have set new benchmarks for durability and efficiency.

- 2023 Global Stainless Steel Pipe Fittings Market Size: Approx. $4.8B, CAGR 5.6% (2022-2028) [Statista]

- Key Demand Drivers: Increasing industrial automation, stricter safety & anti-corrosion regulations, custom solution needs.

- Major Regions: APAC (China, India), North America, Europe.

Industry Standards

ISO 9001, ANSI B16.9, ASTM A403, and DIN standards are widely adopted for butt weld pipe caps, threaded steel cap, and custom stainless steel chimney cap products.

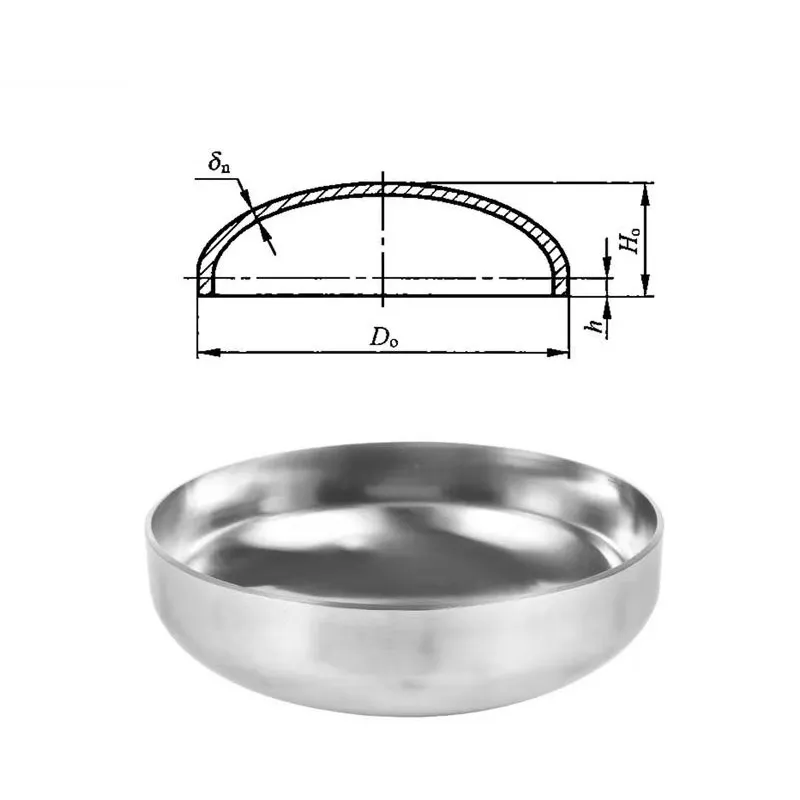

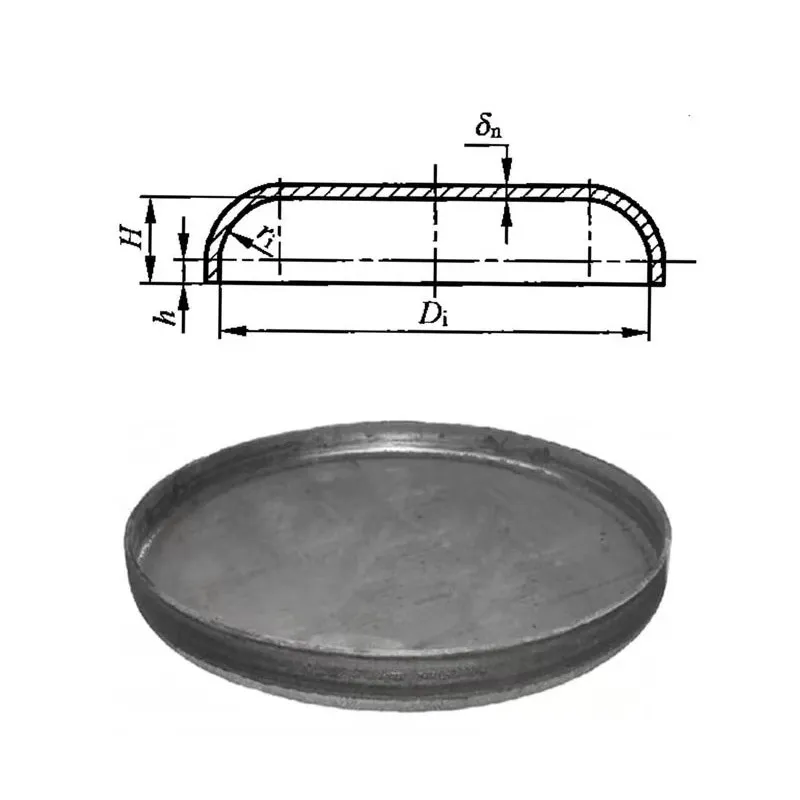

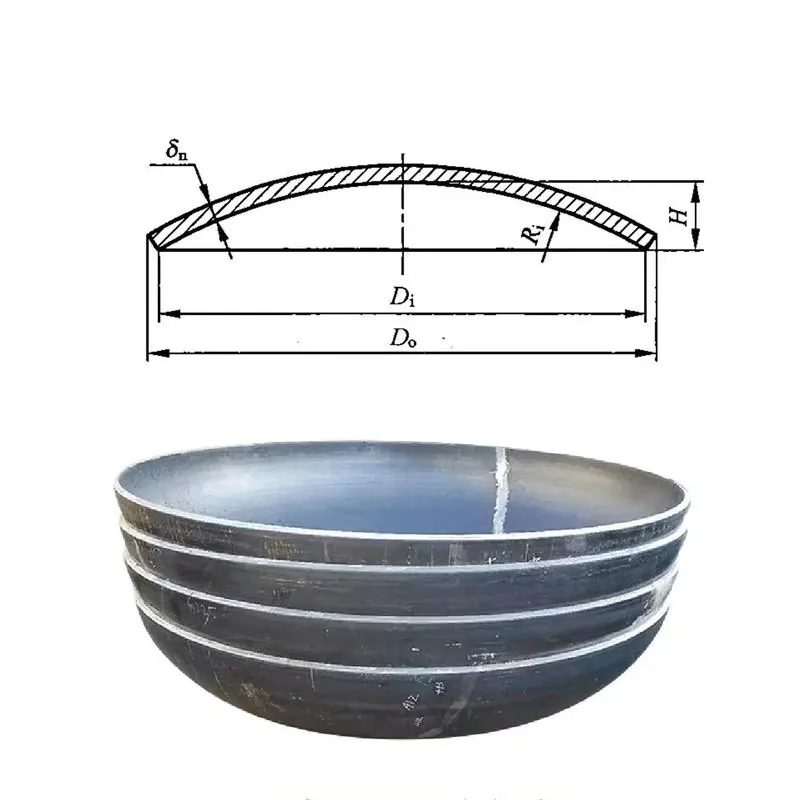

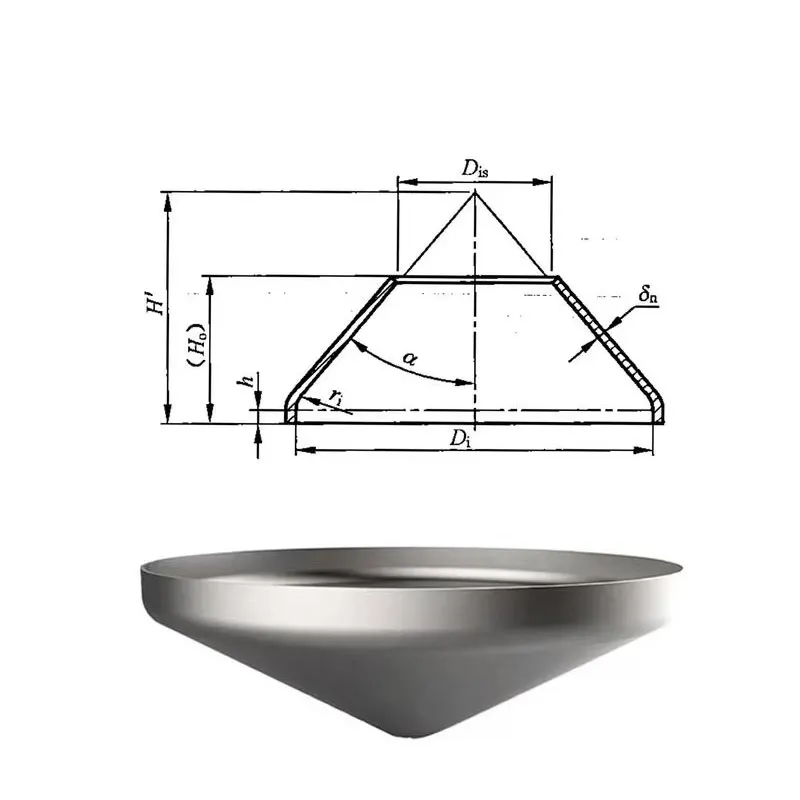

2. Main Technical Specifications and Product Comparison

Understanding crucial parameters helps buyers select the optimal stainless steel cap for their unique engineering needs. Below is a data table summarizing main characteristics for different cap types.

| Product Type |

Material |

Standard(s) |

Connection |

Size Range |

Design Pressure |

Corrosion Resistance |

Application Industries |

| Butt Weld Pipe Cap |

304, 316L, 321, Duplex SS |

ANSI B16.9, ASTM A403 |

Butt Weld |

1/2"–48" (DN15–DN1200) |

≤1500psi |

Excellent |

Oil & Gas, Petrochemical |

| Threaded Steel Cap |

304, 316, 310, Carbon Steel |

ANSI B16.11, ISO 49 |

Female Thread |

1/8"–8" (DN6–DN200) |

≤3000psi |

Good |

Water/Steam/Gas Piping |

| Custom Stainless Steel Chimney Cap |

304/316, Specialty Alloys |

EN 1856-1, UL |

Bolt/Clamp |

Custom |

Varies |

Superior |

HVAC, Ventilation |

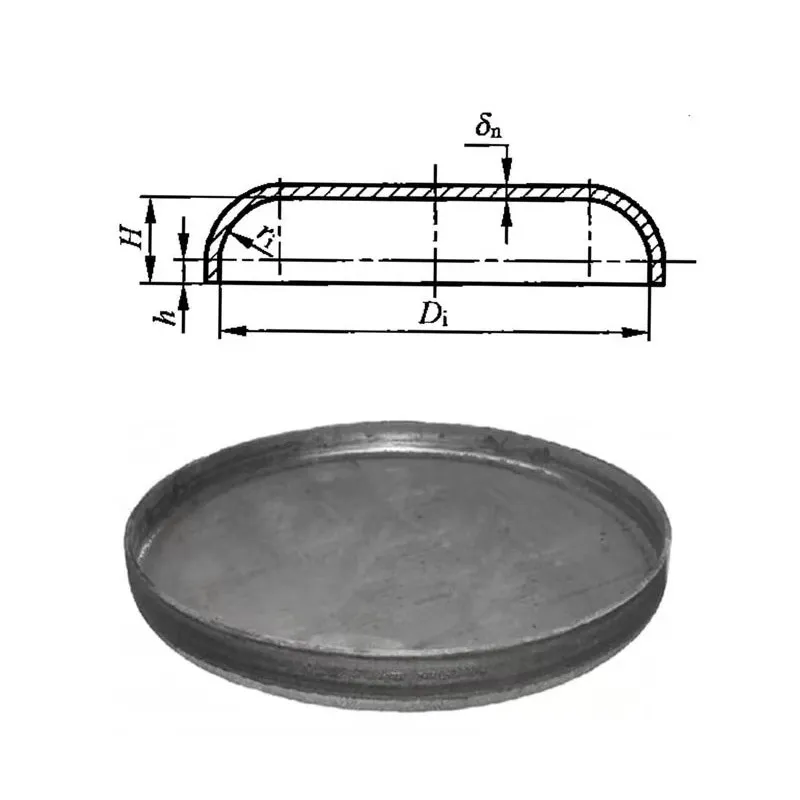

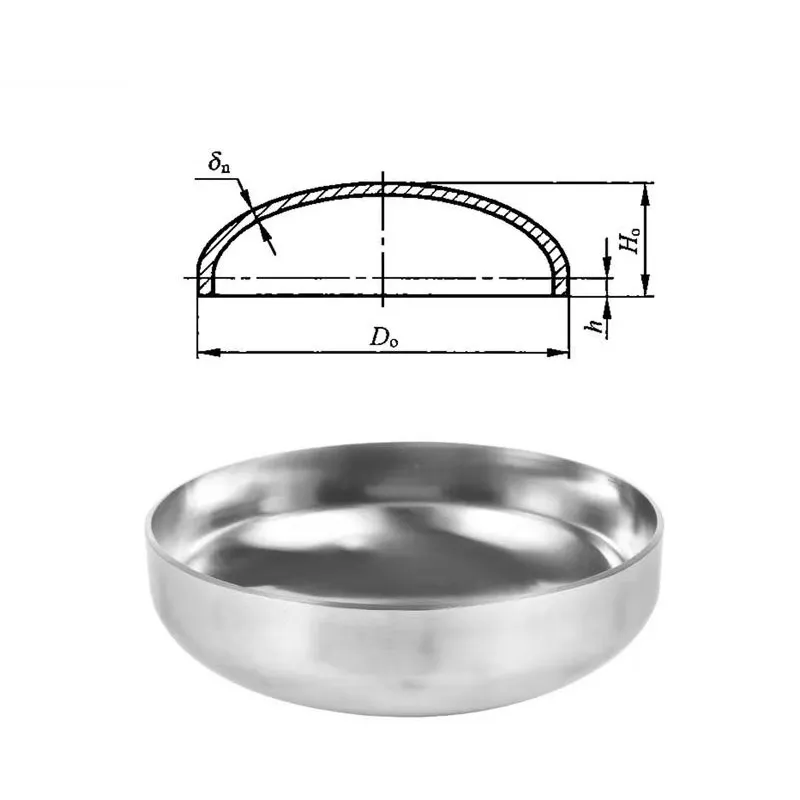

Selected Pipe Cap Specification

- Material Grades: Austenitic (SS304, SS316/316L), Duplex (2205), Super Duplex, Alloy 20

- Wall Thickness: SCH10 to SCH160, XXS

- Manufacturing Methods: Seamless, Welded

- Surface Treat: Pickled, Sand Blasted, Mirror Polish, Powder Coat

3. Stainless Steel Cap Manufacturing Process Explained

1. Material Selection - Premium stainless steel billets/bars are sourced according to ASTM/ISO standards, ensuring metallurgy integrity.

2. Forming - Caps are shaped via hot/cold forging, deep drawing, or spinning. Butt weld caps typically use hot-pressing; threaded caps leverage CNC machining.

3. Heat Treatment - Annealing and solution treatment improve microstructure, stress relief, and increase lifespan (per ASTM A403/A312).

4. Machining & Finishing - Precision CNC machining, threading, and edge beveling to ensure seamless fit. Surface finishes: acid pickling, mirror polish, passivation.

5. Inspection & Testing - 100% visual, dimensions, and pressure tests following ISO 5208, NACE, and in-house criteria. NDT (dye-penetrant, ultrasonic) for high-purity projects.

6. Marking & Packing - Caps are marked per project or standard (ANSI/ASME), packed oil-free or with anti-corrosion wrapping.

Schematic: Stepwise fabrication process (Forging, Machining, Testing)

4. Data Visualization: Pipe Cap Technical Index Comparison

5. Core Advantages and Application Scenarios

Stainless steel cap products from certified manufacturers offer outstanding value in severe environments.

- Anti-Corrosion Resistance to chemicals, saltwater, acids, solvents—ideal for petrochemical and off-shore platforms per NACE MR0175

- High Mechanical Strength Maintains integrity under extreme pressures and temperatures (up to 600°C with SS316Ti)

- Long Service Life Typical lifespan 20–30 years+ in continuous industrial service

- Hygienic, Non-toxic FDA & WRAS compliant options for potable water, food and pharma applications

- Energy Efficiency Leak-proof design prevents energy losses, lowers maintenance

- Tilpasning Dimensions, wall thickness, marking, surface—tailored per client project

Case: Refinery Hydroprocessing Plant

- Client: Sino-Oil Engineering

- Product: 8" & 12" Butt Weld Pipe Cap (SS316L, Sch80)

- Service: Pressure containment in hydrocracking pipeline (140bar/350°C)

- Outcome: 98.6% uptime over three years, zero cap failure, 14% operational cost reduction vs. carbon steel

6. Leading Stainless Steel Cap Manufacturers & Custom Solutions

Choosing the right partner is critical for project success. Here, we compare major stainless steel cap manufacturers and present Rørkappe from Lion-Pipeline as a premier, customizable option.

| Company |

Key Products |

Certifications |

MOQ |

Lead Time |

Global Project Experience |

| Lion-Pipeline |

Butt Weld Cap, Custom Cap, Threaded |

ISO9001, PED, DNV-GL, TUV, FDA |

1 pc |

15–25 days |

80+ countries, 200+ projects |

| Smith Fittings |

Standard Cap |

ISO9001, ASME |

25 pcs |

21–30 days |

45+ countries |

| EuropePipe AG |

EU/DIN Chimney Cap |

ISO, EN 1856, CE |

10 pcs |

20–30 days |

32+ countries |

Customization Process Example

- Application consultation: Suggests grade/thickness per medium and pressure/temperature.

- Drawing confirmation: 3D model & spec validation before production.

- Material traceability: Each lot shipped with EN10204/3.1 Material Test Certificate (MTC).

- Inspection and third-party audits: Per customer requirements (SGS, LR, BV etc).

- Global logistics & after-sales support: Package and delivery tracking plus real-time technical assistance.

7. Real Project Feedback & Application Success Stories

Case: Urban Water Treatment Plant

Installed: 6" threaded steel cap (SS316) for chlorine dosing lines.

Feedback: "No leaks or corrosion after 5 years. Installation is effortless; pipe caps require virtually zero maintenance. Highly trusted brand for municipal projects."

—Waterworks Engineer, South Asia

Case: HVAC Flue System

Product: Custom stainless steel chimney cap (SS304, laser cut)

Performance: High resilience under thermal cycling, retained gloss and finish after 2+ years outdoor exposure.

—Facility Manager, Germany

Who benefits? Stainless steel cap is extensively used in petrochemical plants, municipal water supply, offshore drilling, power stations, and residential or commercial chimneys.

FAQ: Stainless Steel Pipe Cap Technical FAQ

- Q1: What are the advantages of using a butt weld pipe cap over a threaded steel cap?

-

A: Butt weld pipe caps provide a stronger, permanent seal suitable for high-pressure/high-temperature pipelines. They eliminate thread leakage risks, ensure uniform stress distribution, and allow smooth internal bore for pigging/cleaning.

- Q2: Which stainless steel grades are recommended for highly corrosive environments?

-

A: For highly corrosive service, SS316/316L, Duplex 2205, and Super Duplex grades are preferred due to molybdenum and nitrogen alloying, providing superior pitting and stress corrosion resistance.

- Q3: What international standards must stainless steel cap products comply with?

-

A: They should meet at least ASTM A403 (fittings), ANSI B16.9 (welded caps), ANSI B16.11 (threaded), EN 1856-1 (chimney caps), ISO 9001 QMS, plus PED/CE for EU projects.

- Q4: What is the recommended installation torque for threaded steel cap?

-

A: Installation torques depend on size/material, typically 8–40 Nm for 1/2"–2" caps per ASME B1.20.1. Always use correct thread sealant (PTFE tape), and do not overtighten to prevent stress cracking.

- Q5: Can I request a custom marking or branding on pipe caps?

-

A: Yes, leading manufacturers including Lion-Pipeline offer laser or die-stamped markings per your project, including logo, heat number, material grade, and batch traceability for each cap.

- Q6: What test certifications are supplied?

-

A: Each batch includes EN10204/3.1 MTC, and—optionally—NDT, Hydro-Test Report, and Third Party Inspection. All production is traceable via unique batch/lot code.

- Q7: What is the typical delivery cycle and warranty?

-

A: Standard sizes are ready within 10–18 days, larger or custom caps in 21–30 days. Lion-Pipeline offers 24 months warranty, with prompt customer support and global after-sales assistance.

8. Delivery, Warranty, Customer Commitment & Support

- Delivery: Fast dispatch (3–7 days for standard items; 21–30 days for custom) and tracking support globally.

- Warranty: 24-Month product warranty covers material, manufacturing, and premature corrosion; extended plans on request.

- Documentation: Full QAP, pressure tests, material certificates, dimensional reports available per order.

- OEM/ODM Service: One-stop technical solution, 3D CAD support, fast prototyping, worldwide logistics.

- Customer Support: Multilingual technical team, online troubleshooting, on-site audits, and application guidance.

- OEM Partners: Serving top contractors such as CNPC, Veolia, Siemens Energy, and major EPCs.

9. Conclusion: Authority, Compliance, and Value Creation

- By selecting the right stainless steel cap supplier, adhering to international standards (ISO, ANSI, ASTM), and leveraging advanced customization, your project gains optimal reliability, compliance, and ROI.

- Lion-Pipeline's Pipe Cap (product page) embodies top-class manufacturing, backed by ISO9001, PED, and CE certifications, and proven by extensive field experience and client feedback.

- Continue learning and benchmarking from leading forums: