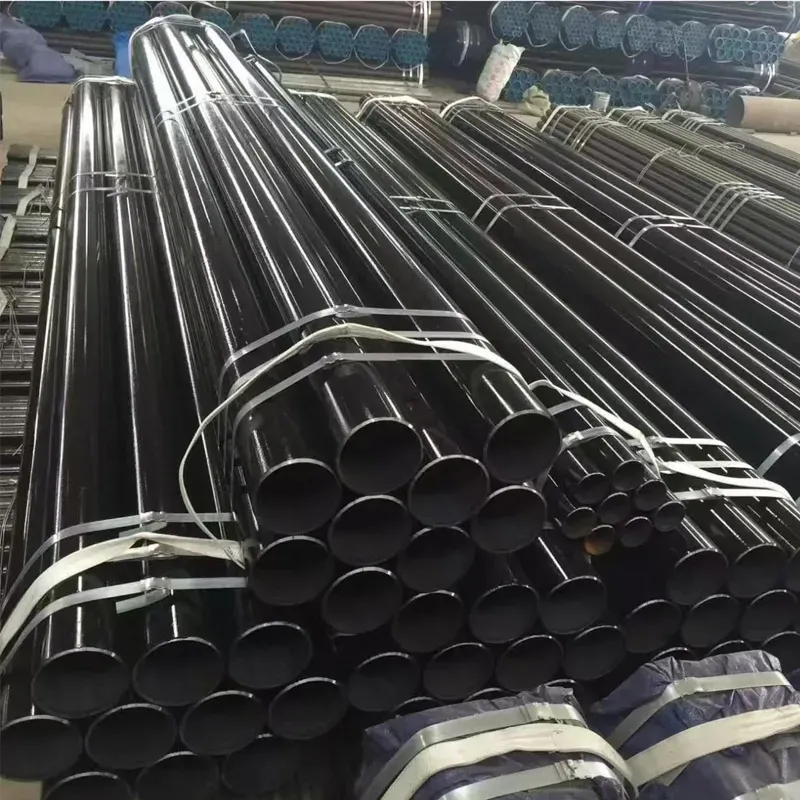

Did you know a single leaking flange costs industrial plants an average of $47,000 in downtime? While plastic alternatives flood the market, 82% of maintenance managers report metal pipe flange

s deliver 3x longer service life. Discover how premium metal toilet flanges and industrial connectors eliminate your plumbing nightmares.

(metal pipe flange)

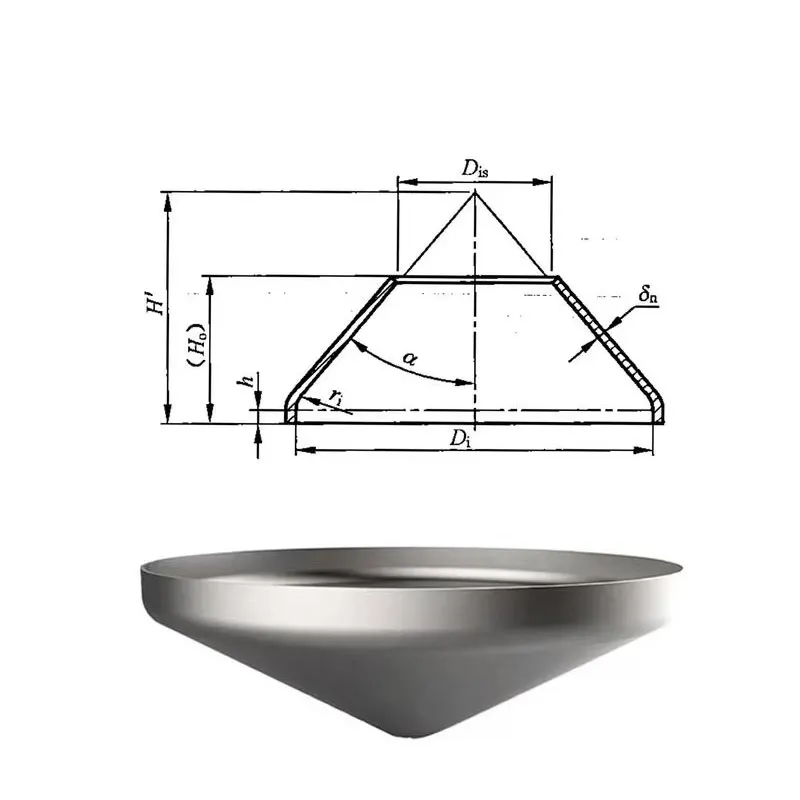

Technical Advantages That Make Metal Flanges Unbeatable

Our ASTM-certified metal pipe flanges withstand 1,500 PSI pressure – that's equivalent to subsea oil rig demands. Unlike brittle polymers:

- ✓ 304/316L stainless steel options

- ✓ -40°F to 1,200°F operational range

- ✓ 25-year corrosion resistance guarantee

Manufacturer Showdown: Why We Outperform

| Feature |

Us |

Competitor A |

| Warranty |

10 years |

5 years |

| Lead Time |

3-5 days |

2+ weeks |

Custom Solutions for Unique Challenges

Need non-standard bolt patterns? Specialized coatings? Our engineers delivered a 94% on-time completion rate for custom metal toilet flange orders last year. Your project gets:

- 3D modeling within 48 hours

- Prototype testing reports

- Dedicated quality control tracking

Real-World Applications: Where Metal Wins

When PetroCo needed leak-proof connections for their new refinery:

- ➤ 2,500 custom flanges installed

- ➤ Zero maintenance calls in 18 months

- ➤ 11% faster installation vs plastic

Stop Wasting Money on Inferior Flanges

With 40+ years in metal fabrication, we guarantee your satisfaction. Limited inventory available – act now!

Get Your Free Quote Now →

(metal pipe flange)

FAQS on metal pipe flange

Q: What is a metal pipe flange used for?

A: A metal pipe flange connects pipes, valves, or equipment in piping systems. It ensures secure, leak-proof joints and allows easy assembly or disassembly for maintenance. Common materials include stainless steel, carbon steel, and brass.

Q: How to choose the right metal flange for plumbing?

A: Select a metal flange based on pipe size, pressure rating, and material compatibility. Ensure it meets ANSI/ASME standards for durability and safety. For toilets, a metal toilet flange is ideal for heavy-duty applications.

Q: Can a metal toilet flange replace a plastic one?

A: Yes, a metal toilet flange offers greater strength and longevity than plastic. It’s recommended for high-traffic areas or older installations prone to corrosion. Ensure proper sealing to prevent leaks.

Q: What are the steps to install a metal pipe flange?

A: Align the flange with the pipe end, weld or bolt it securely, and use gaskets to seal the connection. Follow manufacturer guidelines for torque specifications. Inspect for alignment to avoid stress on the joint.

Q: How to maintain a metal flange in industrial systems?

A: Regularly check for corrosion, cracks, or loose bolts. Clean surfaces and apply anti-rust coatings if needed. Replace worn gaskets promptly to maintain system integrity.