Factory Prefabricated Products: The Future of Prefabricated Pipework Solutions

In the ever-evolving industrial landscape, prefabricated pipework is setting a new standard in pipeline engineering, offering advantages in cost, quality, and sustainability. Leveraging innovations like customized steel pipe, automated welding, and advanced prefab pipe assemblies, Factory Prefabricated Products (official website) delivers tailored pipeline systems for sectors from petrochemical to municipal waterworks.

- Industry trend (2023): Global prefabricated piping market reached USD 10.4 billion (Source: MarketsandMarkets), and is expected to register CAGR 6.7% till 2030 driven by digital fabrication & rising demand for modular plants.

- Why prefabricated pipework? Reduces onsite labor by up to 60%, minimizes installation time and ensures consistent quality control.

- Main related terms: customized steel pipe, prefabricated pipe, prefab pipe, prefab pipework, modular steel piping, system prefabrication.

Prefabricated Pipework: Technical Parameters & Market Comparison

| Item |

Parameter |

Industry Standard |

Fabrikspræfabrikerede produkter |

| Pipe Materials |

Carbon steel, Stainless steel, Alloy steel |

API 5L, ASTM A106, ISO 3183 |

Q235B, 20#, SS304/316, Alloy steels |

| Diameter Range |

DN15 to DN1200 |

ANSI B36.10/19 |

DN20–DN1400, ±0.5mm tolerance |

| Wall Thickness |

2.5–80mm (project dependent) |

ISO 4200 |

Up to 100mm |

| Pressure Class |

PN6–PN160/CL150–CL900 |

ANSI, DIN, GB/T 9113 |

Customized (PN10–PN160) |

| Pipe Connection |

Welded, Flanged, Threaded |

ISO, ASME B16.5 |

Automatic welding (99%), flexible flange |

| Corrosion Protection |

PE/PUR Coating, Galvanizing, FBE |

DIN 30670, AWWA C213 |

Epoxy (Fusion Bonded), 3PE/2PE/PP/Hot-dip galvanized |

| Operational Life |

20–50 years |

ISO 9001:2015 |

35+ years (cert. by TÜV, SGS) |

Notably, Factory Prefabricated Products integrates advanced CNC cutting and beveling lines and multi-axis robotic welding. The process is certified by ISO 9001, ISO 14001, and ASME, ensuring every prefabricated pipework piece matches project specs. This product is tailored for complex industrial applications: combined heat & power, chemical transfer, fire protection, and more.

Technical Parameter Trends (2018–2024): Visualized

Prefabricated Pipework Manufacturing Process Flow

Step-by-step process:

- 1. Raw Material Inspection: Steel pipes undergo spectrographic analysis and visual inspection in line with ISO 9001.

- 2. CNC Cutting & Beveling: Pipes are cut to precise lengths & beveled edges for optimum welding by automated CNC systems.

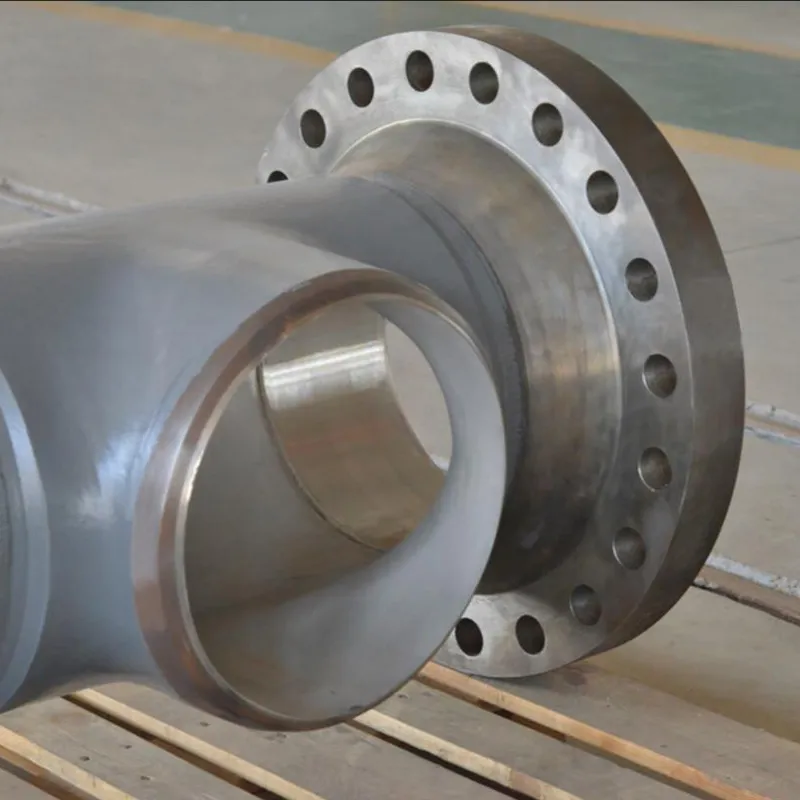

- 3. Assembly & Mock-up: Fittings (elbows, tees, flanges – ASME B16.9/16.5 rated) are positioned, spools preassembled.

- 4. Automatic Welding: Robotic MIG/TIG welding ensures 360° seam integrity with 99% x-ray pass rate.

- 5. NDT & Hydrostatic Testing: Ultrasonic/RT, pressure test up to 1.5× design; compliance with API 570.

- 6. Coating & Preservation: External 3PE/FBE lining for anti-corrosion; internal epoxy or cement lining as per application.

- 7. Pre-assembly, Packing & Delivery: Factory setup checks, modular packing, documented traceability for instant site installation.

Factory-controlled production: Sea-change in quality, safety, and installation speed for prefab pipework.

Main Manufacturing Techniques: Hot rolling, cold drawing, casting, forging, CNC precision machining. Key quality gates: Material PMI test, weld seam x-ray, coating thickness check, dimensional & visual inspection.

Applications & Industry Case Studies

- Petrochemical (Oil Refineries): Reduces turn-around time by 45%, enables rapid modular plant expansion, minimizes hot work exposure.

- District Heating/Cooling: Thermal expansion control with flexible joints; prefab pipe spools speed up buried network construction, cut leakage by 60%.

- Water & Wastewater Treatment: Accelerates project delivery; anti-corrosion inner linings (cement/epoxy) extend life, proven in 30+ municipal projects.

- Fire Suppression/Industrial Gases: Strict tolerance (≤±1.0mm), high purity assembly for zero-leakage systems.

- Client Feedback: “Installation of prefabricated pipework from Factory Prefabricated Products resulted in a 32% cost reduction and 4 weeks faster start-up” – Sinopec Project Supervisor

Notable Collaboration: Factory Prefabricated Products supplied 18,000m prefab piping to China Petroleum & Chemical Corp., meeting ANSI/ASME, ISO 9001 quality and full project documentation requirements.

Factory Prefabricated Products vs Major Market Suppliers

| Feature |

Fabrikspræfabrikerede produkter |

International Competitor A |

Regional Supplier B |

| Material Range |

Stainless, Carbon, Alloy Steel, HDPE |

Stainless, Carbon steel |

Carbon steel only |

| Diameter (Max) |

DN1400 |

DN1000 |

DN600 |

| Certifications |

ISO 9001, 14001, ASME, API |

ASME, ISO 9001 |

Basic local |

| Production Capacity |

100,000+ meters/month |

50,000 meters/month |

15,000 meters/month |

| Automated Welding |

Robotic MIG/TIG (99%) |

Manual (60%) |

Manual only |

| Onsite Installation Support |

Yes; 48h global response |

Limited |

No |

| Warranty |

Up to 10 years (against corrosion, leakage) |

1 year |

6 months |

Conclusion: The prefabricated pipework solution by Factory Prefabricated Products stands out for its advanced certifications, production scale, broader technical capabilities and premium after-sales support.

Customization Options & Typical Prefab Pipework Solutions

**Customized steel pipe** offerings are fully engineered to your process data and site constraints. Key prefab pipework customizations include:

- Material Upgrades: Duplex SS, Hastelloy alloys for corrosive/critical applications.

- Dimension Precision: CNC controlled ±0.5mm, on flanged, threaded, or welded ends.

- NDT Protocols: 100% RT/UT of weld seams for chemical or nuclear sectors.

- Functional Modules: Spools, skids, headers, integrated valve stations and supports.

- Engineering Services: 3D spool modeling (Tekla, CAD), flow simulation, stress analysis, prefab-to-site mapping.

- Packaging: Modules labeled per BIM plan, protective wrapping for rapid field fitment.

Kontakte Fabrikspræfabrikerede produkter for a tailored offer, including specification drawings, test certification, and lifetime technical support.

Data Visualization: Key Statistics on Performance & Durability

FAQs: Expert Answers to Professional Prefab Pipework Questions

- 1. What are the main materials used for prefabricated pipework?

- The most common are carbon steel (Q235, API 5L), stainless steel (304/316), alloy steels, HDPE, and special alloys (e.g., Duplex, Inconel).

- 2. How is dimensional accuracy controlled?

- CNC cutting and 3D laser measurement ensure tolerances within ±0.5mm, meeting ANSI and ISO dimensions standards.

- 3. Which welding standards are met?

- Welds comply with ASME IX, API 1104, and EN 287; 99% of weld seams are robotically executed, and 100% radiography or ultrasonic tested.

- 4. What anti-corrosion protective measures are applied?

- Standard options: Fusion bonded epoxy (FBE), 3PE/2PE, galvanizing, or internal cement/PU lining, based on service media.

- 5. What is the typical delivery lead time?

- For standard modules: 2–6 weeks after drawing approval; custom engineered spools: 4–10 weeks. Global shipping supported.

- 6. What certifications does Factory Prefabricated Products hold?

- ISO 9001/14001, ASME, API 5L, PED, OSHA, API 570, plus third-party TPI by TÜV or SGS upon request.

- 7. What project support do you provide?

- Full technical documentation, traceability, onsite supervision (24–48h response), BIM-based pre-installation guides, and up to 10 years product warranty.

Delivery Terms, Warranty & Customer Support

- Standard Delivery Window: 2–8 weeks depending on batch, size & customization.

- Warranty: Up to 10 years (material, welding, anti-corrosion under normal operation).

- Pre-shipment Inspection: ISO/ANSI/EN standard acceptance; third-party witness available.

- Technical/Installation Support: 365/24h hotline, remote & onsite guidance, video call troubleshooting.

- Documentation Supplied: Material batch certificates, weld/NDT reports, assembly drawings, full traceability.

- After-sales Service: Rapid parts shipment, installation team dispatch within 48h in Asia/Europe/Africa.

All prefabricated pipework projects have a dedicated project manager & technical support engineer assigned for total peace of mind.