Customized steel pipes are essential components in various industries, offering tailored solutions for specific project requirements. This article explores the applications, manufacturing processes, material considerations, and advantages of customized steel pipe products, including specialized fittings like the 4 stainless steel tee and 2-inch stainless steel tee, as well as structural components such as the brushed steel newel post cap. The discussion also covers technical aspects like bendable stainless steel tubing and its variants, providing a comprehensive overview of their industrial relevance.

The Versatility of Customized Steel Pipe

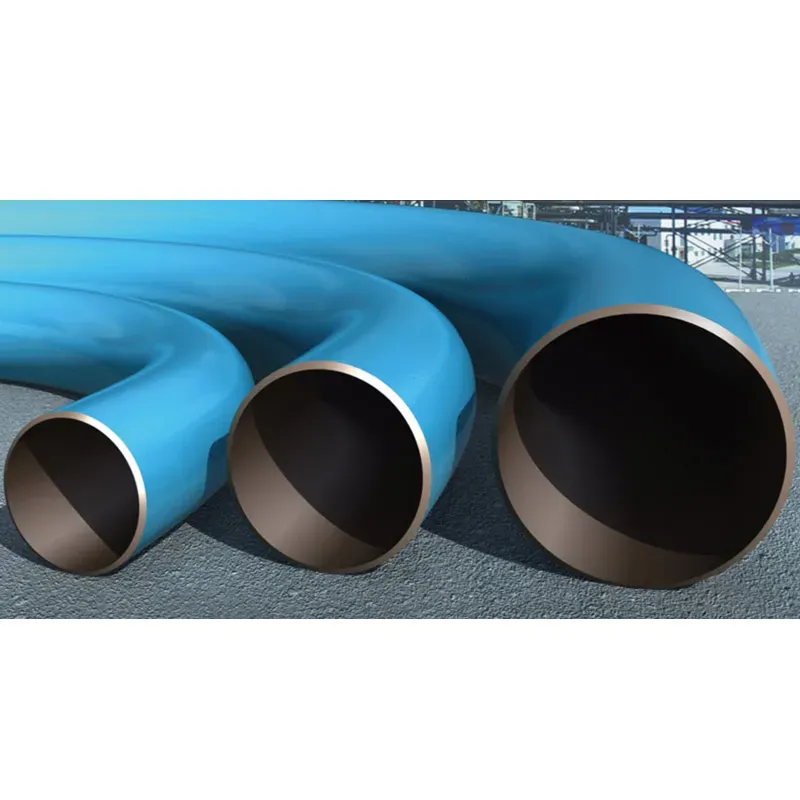

Customized steel pipe serves diverse applications across multiple sectors, including construction, oil and gas, and manufacturing. These pipes can be fabricated to exact specifications, ensuring optimal performance in various operating conditions. The ability to customize dimensions, thickness, and connection types makes them indispensable for complex piping systems.

One common application involves the use of tees, such as the 2 stainless steel tee, which facilitates fluid distribution in pipelines. These fittings are particularly valuable in chemical processing plants where precise flow control is critical. The 4 stainless steel tee is another essential component, often employed in high-pressure systems due to its superior structural integrity and leak-proof connections.

In architectural applications, components like the brushed steel newel post cap provide both functional and aesthetic benefits. These caps protect stair railings while enhancing visual appeal in commercial and residential buildings. Similarly, the stainless steel cap is widely used in protective covers for outdoor structures, offering durability against weather elements. For industrial exhaust systems, the chimney cap steel ensures long-term performance by preventing debris accumulation and resisting corrosion.

Material Selection for Customized Steel Pipe

The performance of customized steel pipe depends heavily on material properties and composition. Engineers must consider factors such as corrosion resistance, tensile strength, and temperature tolerance when selecting materials. Stainless steel alloys, particularly grade 304, are preferred for many applications due to their excellent balance of durability and workability.

Stainless steel 304 is commonly specified for bending 304 stainless steel tubing because it maintains its structural properties during forming processes. This grade offers good weldability and formability while resisting oxidation in various environments. For applications requiring greater flexibility, bendable stainless steel tubing made from specialized alloys provides the necessary ductility without sacrificing strength.

Thinner gauges, such as those used in bending 3 8 stainless steel tubing, are often selected for precision applications where tight radius bends are necessary. The material thickness directly impacts the pipe's pressure rating and fatigue resistance. Components like the 2-inch stainless steel tee benefit from carefully selected materials that ensure resistance to chemical attack and mechanical stress in demanding industrial environments.

Manufacturing and Processing Techniques of Customized Steel Pipe

The production of customized steel pipe involves multiple precision manufacturing stages to achieve the required specifications. Modern fabrication facilities employ advanced CNC machinery and laser measurement systems to ensure dimensional accuracy. Quality control begins at the material selection phase and continues through every production step.

For specialized products like bendable stainless steel tubing, manufacturers use mandrel bending techniques to achieve smooth, wrinkle-free curves. The process for bending 3 8 stainless steel tubing typically involves cold-working methods that preserve the material's grain structure. These techniques prevent wall thinning and maintain the tubing's pressure containment capabilities.

Bending 304 stainless steel tubing requires particular attention to heat input and work hardening effects. Manufacturers often use induction heating to maintain optimal temperatures during forming operations. Post-processing treatments like stress relieving and passivation ensure the final product meets corrosion resistance standards. These meticulous processes guarantee that customized pipes maintain their performance characteristics throughout their service life.

The demand for customized steel pipe continues to grow across industries due to its unparalleled adaptability and reliability in meeting specific project requirements. From essential fittings like the 2-inch stainless steel tee to specialized components such as bendable stainless steel tubing, these products have become indispensable in modern infrastructure development. The ability to precisely engineer pipes and fittings to exact specifications ensures optimal performance in diverse applications, ranging from high-pressure industrial systems to architectural features requiring both functionality and aesthetic appeal.

As industries continue to evolve, the importance of customized steel pipe solutions will only increase. Advanced manufacturing techniques, coupled with rigorous material selection processes, enable the production of components that withstand extreme conditions while maintaining structural integrity. Whether it's the 4 stainless steel tee for complex piping networks or the brushed steel newel post cap for architectural applications, these customized solutions demonstrate how tailored engineering can address unique challenges across multiple sectors. The ongoing development of new alloys and fabrication methods promises to further expand the capabilities and applications of customized steel piping systems in the future.