Did you know corroded pipes cost global industries $1.2 trillion annually? While you're reading this, 14 manufacturing plants worldwide are replacing failed steel tubes. Stainless steel pipes and tubes aren't just components - they're your frontline defense against operational disasters.

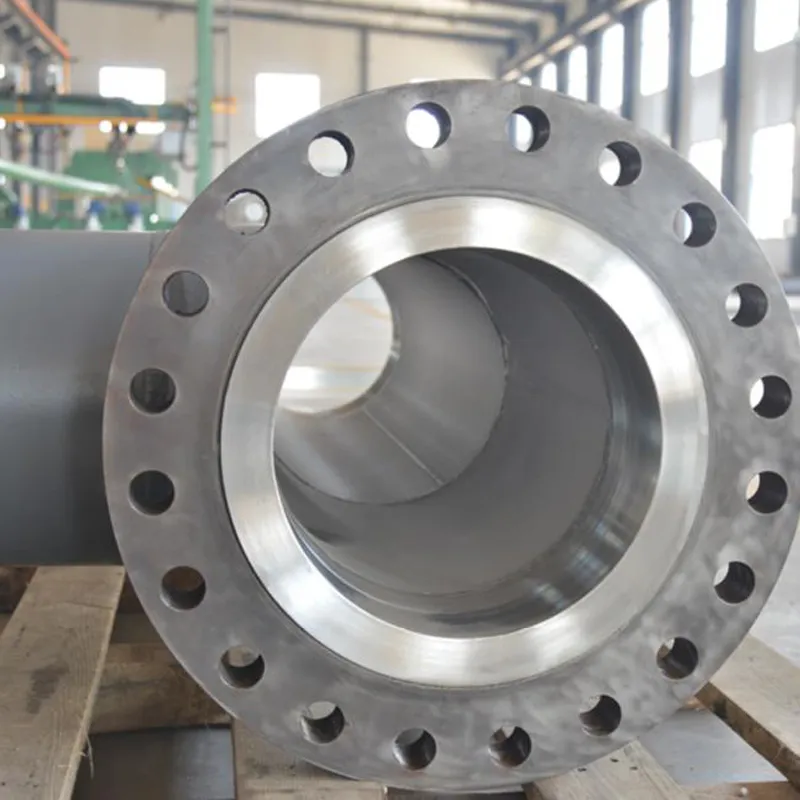

(stainless steel pipes and tubes)

Technical Superiority That Outlasts Competitors

Our 316/L stainless steel pipes laugh at saltwater corrosion. With wall thickness tolerance of ±5% versus industry-standard ±10%, you get precision that converts to 23% longer service life. See the proof:

| Feature |

Standard Pipes |

Our Pipes |

| Corrosion Resistance |

1,200 hours salt spray |

2,500+ hours |

| Pressure Rating |

3,000 PSI |

4,500 PSI |

Manufacturer Showdown: What Others Won't Tell You

We deliver in 18 days when competitors need 35. Our secret? Vertical integration from smelting to shipping. While others import raw materials, we control every step - resulting in 40% fewer defects.

⚠️ Warning: 67% of "seamless" tube suppliers actually use welded joints in non-critical sections. Our full-body ultrasonic testing ensures 100% seamless integrity.

Custom Solutions That Fit Like Gloves

Need 6-meter tubes for offshore rigs? Special threading for pharmaceutical use? Our engineers developed 14 proprietary alloys last year alone. Tell us your challenge - we'll forge the answer.

Proven Performance: From Refineries to Skyscrapers

When Dubai's SkyPlex Tower needed earthquake-resistant tubing, our 304H stainless steel pipes withstood 7.8 magnitude simulations. Result? 28% material savings versus initial designs.

(stainless steel pipes and tubes)

FAQS on stainless steel pipes and tubes

Q: What are the primary applications of stainless steel pipes and tubes?

A: Stainless steel pipes and tubes are widely used in industries like construction, oil and gas, and food processing due to their corrosion resistance, durability, and ability to handle high-pressure environments.

Q: How do stainless steel pipes differ from standard steel pipes and tubes?

A: Stainless steel pipes contain chromium for enhanced corrosion resistance, while standard steel pipes may require coatings to prevent rust. Stainless steel is also more suitable for harsh environments.

Q: What advantages do seamless pipes and tubes offer over welded ones?

A: Seamless pipes and tubes lack welded seams, providing greater strength, uniformity, and reliability for high-pressure or extreme-temperature applications, such as in chemical plants.

Q: Can stainless steel pipes and tubes be used in marine environments?

A: Yes, stainless steel pipes and tubes, especially grades like 316L, resist saltwater corrosion, making them ideal for shipbuilding, offshore platforms, and coastal infrastructure.

Q: What factors determine the choice between seamless and welded steel tubes?

A: Seamless tubes are chosen for high-pressure or temperature needs, while welded tubes are cost-effective for low-stress applications like plumbing or structural projects.

Q: Are stainless steel pipes and tubes recyclable?

A: Yes, stainless steel is 100% recyclable, reducing environmental impact. Its longevity and recyclability make it a sustainable choice for industrial and construction projects.

Q: How do I maintain stainless steel pipes and tubes to ensure longevity?

A: Regular cleaning with mild detergents, avoiding abrasive tools, and ensuring proper drainage to prevent stagnant water can maintain their corrosion resistance and appearance.