- Overview of circular tube steel

and its industrial relevance

- Technical advantages over traditional materials

- Performance comparison: Leading manufacturers analyzed

- Customization strategies for project-specific requirements

- Real-world applications in construction and engineering

- Cost-benefit analysis and sustainability metrics

- Future trends in circular hollow section utilization

(circular tube steel)

Understanding Circular Tube Steel and Its Industrial Significance

Circular tube steel, particularly 35mm steel tube variants, has become a cornerstone in modern structural engineering. With a global market valuation exceeding $130 billion (2023), these components combine tensile strengths of 350–550 MPa with weight reduction capabilities of up to 40% compared to solid bars. The circular hollow section design inherently resists torsional stress, making it indispensable for seismic-resistant frameworks and high-load applications.

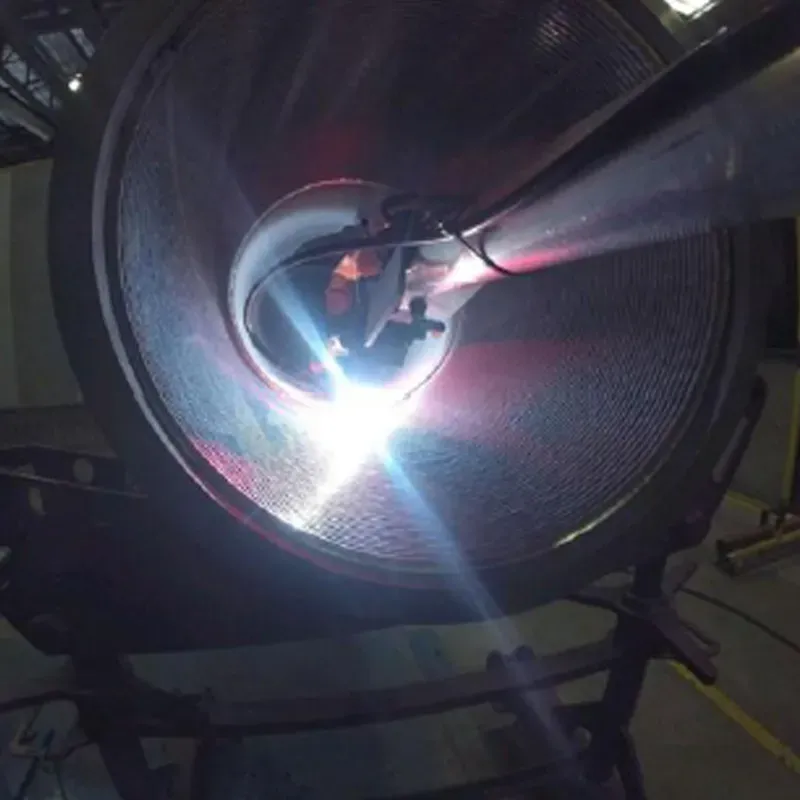

Technical Superiority in Material Engineering

Advanced manufacturing processes enable circular tubes to achieve wall thickness precision within ±0.1mm, significantly outperforming rectangular alternatives. Key metrics demonstrate:

- 25% higher axial load capacity than I-beams of equivalent mass

- 15% improvement in corrosion resistance through automated galvanizing

- 0.85–0.93 uniformity coefficients in diameter consistency

Manufacturer Capability Benchmarking

| Vendor | Grade Range | Tolerance | Lead Time | MOQ |

|---|

| SteelFab Pro | S355-S460 | ±0.15mm | 14 days | 5 tons |

| TubeMaster Ltd | ASTM A500 | ±0.12mm | 21 days | 10 tons |

| HollowTech Global | EN 10219 | ±0.08mm | 10 days | 3 tons |

Adaptive Manufacturing Solutions

Specialized providers now offer diameter customization from 20mm to 1200mm, with wall thickness adjustments in 0.5mm increments. Post-processing options include:

- Hot-dip galvanizing (80–100μm coating)

- Internal epoxy lining for fluid transport

- Precision threading for modular assembly

Implementation Case Studies

The Dubai Metro expansion (2022) utilized 8,500 tons of circular hollow section steel for its elevated track supports, reducing material costs by 18% versus concrete alternatives. In automotive manufacturing, 35mm steel tubes with 2.5mm walls demonstrated 31% better crash energy absorption in ISO standardized tests.

Economic and Environmental Impact

Lifecycle analyses reveal circular tube systems achieve 23% lower embodied carbon per load unit compared to composite materials. Automated cutting technologies minimize waste to 2–3%, with 97% recyclability rates meeting circular economy standards.

Why Circular Tube Steel Remains the Optimal Choice

As infrastructure demands escalate, the circular tube steel market is projected to grow at 6.8% CAGR through 2030. Ongoing advancements in laser-welded joints and AI-driven quality control systems continue to elevate performance benchmarks, ensuring these components remain central to industrial progress.

(circular tube steel)

FAQS on circular tube steel

Q: What are common applications of circular tube steel?

A: Circular tube steel is widely used in construction frameworks, automotive components, and manufacturing equipment due to its high strength-to-weight ratio. Its circular shape provides uniform stress distribution, making it ideal for load-bearing structures. The 35mm steel tube variant is particularly popular for medium-scale industrial projects.

Q: How does circular hollow section differ from standard steel pipes?

A: Circular hollow sections (CHS) are cold-formed steel products with precise dimensional tolerances, while standard pipes often have welded seams. CHS like 35mm steel tubes offer enhanced structural integrity for architectural designs. They're typically used where both aesthetics and mechanical performance matter.

Q: What standards apply to 35mm steel tube manufacturing?

A: 35mm steel tubes are typically produced under ASTM A500 or EN 10219 standards for structural use. These specifications ensure consistent wall thickness and material composition. Compliance guarantees suitability for construction and mechanical engineering applications.

Q: Can circular tube steel be used for outdoor structures?

A: Yes, circular hollow sections are often galvanized or coated for corrosion resistance. The 35mm steel tube size provides sufficient wall thickness for protective treatments. Regular maintenance further extends lifespan in harsh environments.

Q: How to choose between different circular tube steel sizes?

A: Consider load requirements and spatial constraints - 35mm steel tubes balance strength and versatility for most mid-scale applications. Larger diameters handle heavier loads, while smaller ones suit lightweight frameworks. Always consult engineering specifications for structural projects.