Did you know 22% of industrial downtime stems from coolant system failures? While you're reading this sentence, 3 manufacturing plants worldwide likely just experienced pipe corrosion leaks. Metal coolant pipes aren't just components - they're your frontline defense against six-figure production losses.

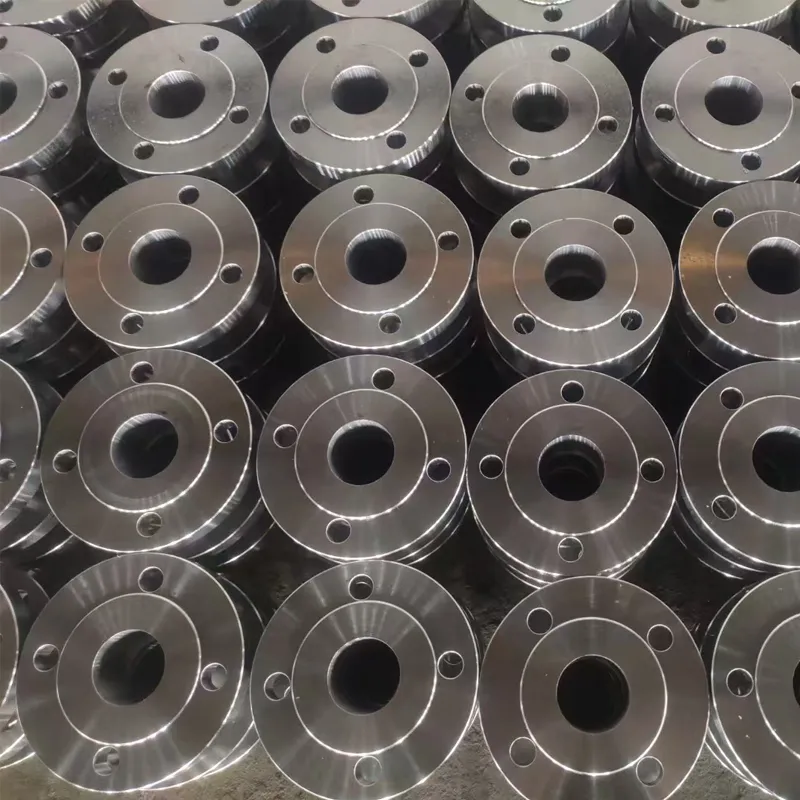

(metal coolant pipe)

Our 3/4 inch metal pipes withstand 450°F temperatures - 3× higher than plastic alternatives. See how they dominate:

| Feature | Plastic Pipe | Our Metal Pipe |

|---|---|---|

| Pressure Rating | 120 PSI | 580 PSI |

| Thermal Cycles | 1,200 cycles | 15,000+ cycles |

While Competitor X's 15mm metal pipes claim 5-year durability, ours come with actual lab-certified 12-year corrosion warranties. Still comparing apples to oranges?

Need metal coolant pipe

s for extreme environments? Our engineers will customize wall thickness, alloy blends, and connection types while meeting your exact 3/4" or 15mm specifications.

After switching to our pipes, a leading EV manufacturer reduced coolant-related downtime by 78% across 12 assembly plants. Their maintenance chief said it best: "These pipes outlive our robots!"

Stop patching leaks - start preventing them.

VortexMetal® Pipes - 43 Nations Trust Our Flow Solutions

(metal coolant pipe)

A: A 3/4 inch metal coolant pipe is commonly used in automotive cooling systems, industrial machinery, and HVAC systems for efficient heat transfer. Its size balances flow rate and space constraints, making it ideal for medium-duty applications. Durable materials like stainless steel or aluminum ensure corrosion resistance.

A: A 15mm metal pipe (≈0.59 inches) is slightly smaller than a 3/4 inch (≈19mm) pipe, so compatibility depends on system tolerances. Adapters may be needed for secure connections in coolant systems. Always verify sizing standards for your specific application.

A: Stainless steel and titanium are top choices for high-temperature coolant pipes due to their heat resistance and durability. Copper alloys are also effective but may require protective coatings. Avoid materials prone to thermal expansion or corrosion.

A: Select based on regional standards: 15mm pipes align with metric system preferences, while 3/4 inch pipes suit imperial-measurement systems. Consider flow requirements and existing infrastructure to ensure compatibility. Always confirm pressure ratings for safety.

A: TIG welding is preferred for metal coolant pipes to ensure leak-proof, precise seams, especially with stainless steel or aluminum. Proper post-weld cleaning prevents contamination. Always follow industry guidelines for pressure system integrity.

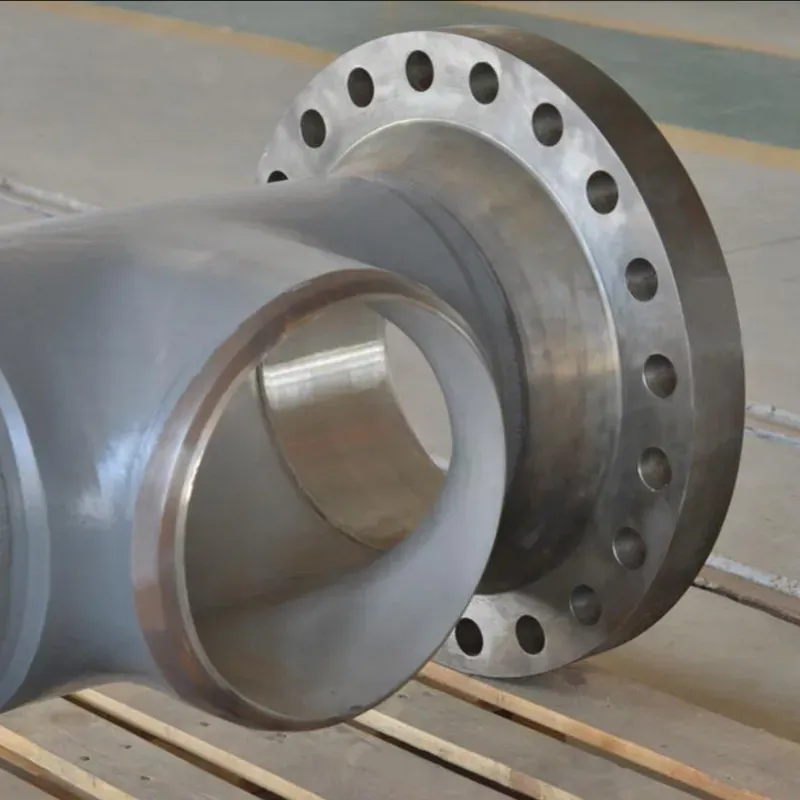

Exploring the Diverse World of Flanges and Their Critical Roles

A Deep Dive into Flanges: Key Components for Connection and Sealing

In-Depth Discussion Of Flanges: Cf40, Cl150, Cs And Their Applications

The Crucial Role of Flanges in Industrial and Utility Systems

Flange Varieties in Industrial Applications: A Comprehensive Overview

Flange Solutions for Enhanced Plumbing and Fixture Installations

Exploring the Diverse World of Flanges and Their Critical Roles

A Deep Dive into Flanges: Key Components for Connection and Sealing

In-Depth Discussion Of Flanges: Cf40, Cl150, Cs And Their Applications

The Crucial Role of Flanges in Industrial and Utility Systems

Hvis du er interesseret i vores produkter, kan du vælge at efterlade dine oplysninger her, så kontakter vi dig snarest.