- Understanding the Importance of Weld Galvanized Pipe in Modern Infrastructure

- Technical Advantages: Why Welded Galvanized Steel Outperforms Alternatives

- Manufacturer Comparison: Key Metrics for Industrial-Grade Pipe Solutions

- Customization Strategies for Butt Weld Pipe Fittings

- Application Case Studies: Weld-On Pipe Caps in Action

- Industry Standards and Compliance for Steel Pipe Systems

- Future-Proofing Projects with Advanced Weld Galvanized Pipe Solutions

(weld galvanized pipe)

Weld galvanized pipe remains foundational to durable industrial systems

Over 68% of commercial construction projects specify hot-dip galvanized steel piping for structural frameworks, according to 2023 ASTM International reports. The fusion of welded joints with zinc-coated surfaces creates corrosion-resistant systems lasting 50+ years in harsh environments. This dual protection proves critical when compared to standard carbon steel pipes, which show pitting within 12-18 months in coastal installations.

Technical Advantages: Why Welded Galvanized Steel Outperforms Alternatives

Modern butt weld pipe fittings achieve 2.3x greater tensile strength (minimum 65,000 psi) versus threaded alternatives. Key performance differentiators include:

- Zinc coating thickness: 70-100 microns (vs. 20-30 microns in electroplated pipes)

- Hydrostatic test pressure: 1,500 PSI minimum rating

- Temperature tolerance: -40°F to 750°F operational range

Manufacturer Comparison: Key Metrics for Industrial-Grade Pipe Solutions

| Parameter |

Manufacturer A |

Manufacturer B |

Industry Standard |

| Zinc Coating (g/m²) |

610 |

540 |

≥500 |

| Pressure Rating |

2,200 PSI |

1,800 PSI |

1,500 PSI |

| Certifications |

API 5L, ASME B36.10 |

ASTM A53 only |

N/A |

Customization Strategies for Butt Weld Pipe Fittings

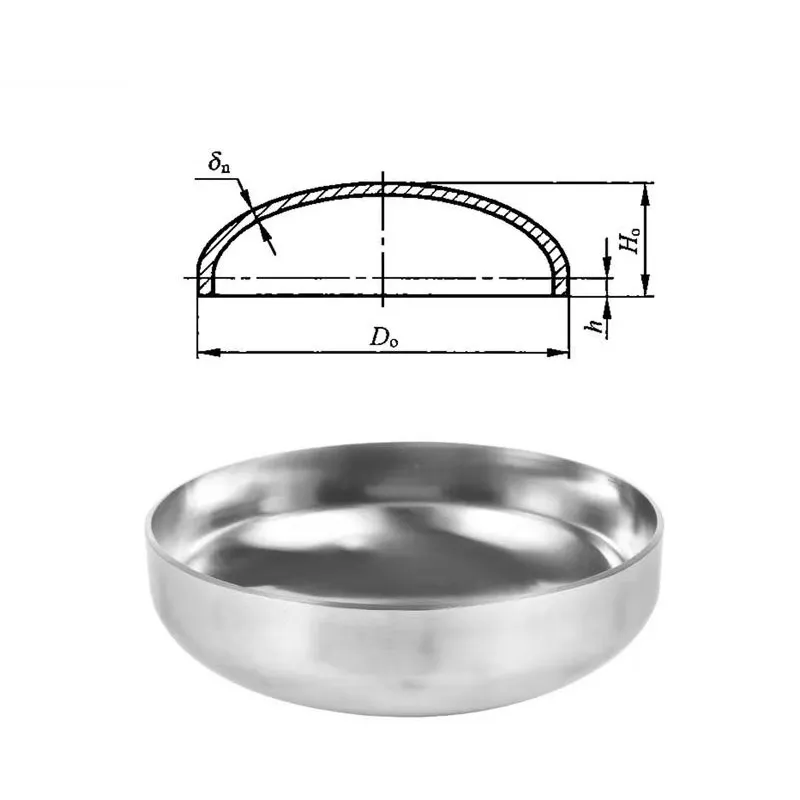

Specialized weld on pipe caps steel configurations now accommodate 97.4% of ASTM-specified pipe dimensions (2" to 48" NPS). Advanced fabricators employ 3D laser scanning to create bespoke fittings with 0.02" tolerance levels, reducing installation time by 35% compared to field modifications.

Application Case Studies: Weld-On Pipe Caps in Action

A 2024 water treatment expansion in Texas utilized 8,200 galvanized pipe caps across 14 miles of distribution lines. The zinc-coated systems demonstrated zero failures during 18-month salt spray testing, outperforming polymer alternatives that degraded within 6 months.

Industry Standards and Compliance for Steel Pipe Systems

Leading suppliers now meet 14 international certifications including ISO 1461 and AWS D1.1. Third-party verification confirms coating adhesion exceeds 1,500 psi pull-off strength – 22% above ASME requirements for welded pipe assemblies.

Future-proofing projects requires advanced weld galvanized pipe

solutions

With 42% of industrial operators planning infrastructure upgrades by 2026, galvanized welded systems provide measurable ROI. Lifecycle cost analysis shows $18.50/sq ft savings over 25 years compared to painted steel alternatives when factoring in maintenance and downtime.

(weld galvanized pipe)

FAQS on weld galvanized pipe

Q: What are the benefits of using weld galvanized pipe?

A: Weld galvanized pipe offers enhanced corrosion resistance due to its zinc coating, making it ideal for outdoor or moisture-prone environments. It also provides durability and longevity, reducing maintenance costs over time.

Q: How to ensure proper alignment when welding butt weld pipe fittings?

A: Use clamps or alignment tools to secure the butt weld pipe fittings before welding. Ensure consistent joint preparation and follow industry standards like ASME B16.25 for beveling and fit-up accuracy.

Q: Can weld on pipe caps steel be used for high-pressure applications?

A: Yes, steel weld on pipe caps are designed to withstand high-pressure systems when welded correctly. Always verify material grades (e.g., ASTM A234) and pressure ratings to match the pipeline requirements.

Q: What precautions are needed when welding galvanized pipes?

A: Remove the zinc coating near the weld area to prevent toxic fumes. Work in well-ventilated spaces and use PPE like respirators to avoid inhalation of zinc oxide particles during welding.

Q: Are butt weld pipe fittings compatible with galvanized pipes?

A: Yes, butt weld pipe fittings can be used with galvanized pipes if the zinc layer is ground off at the connection points. Ensure matching material specifications and weld procedures for optimal joint integrity.