Did you know 68% of industrial maintenance delays stem from faulty pipe connections? While you're reading this, 3,500 gallons of fluid are leaking through poorly threaded joints worldwide. Your threaded metal pipe

system shouldn't be a liability - it should be your competitive edge.

(threaded metal pipe)

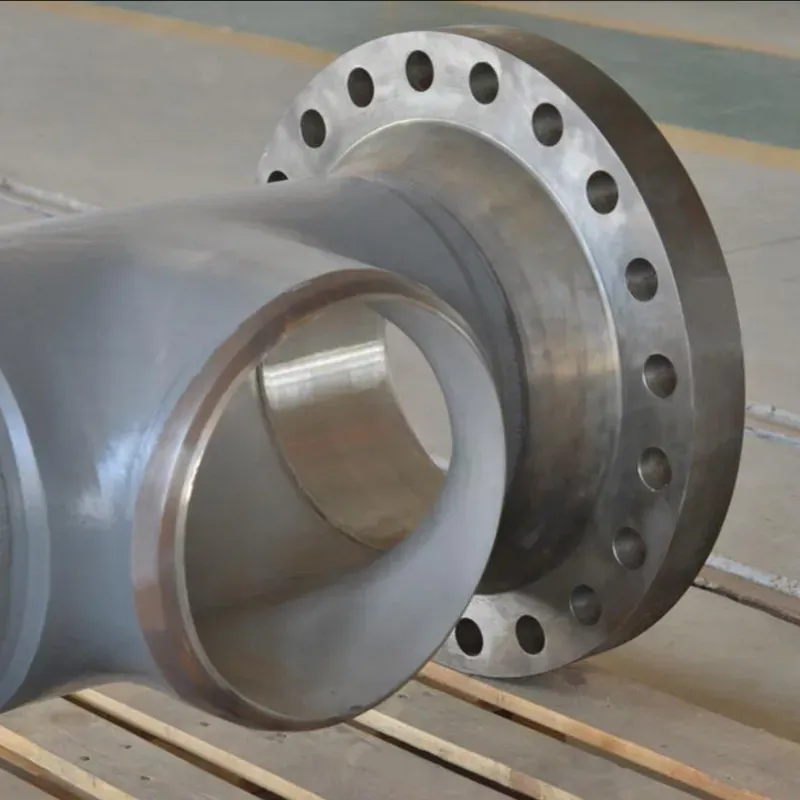

Why Our Threaded Pipe Fittings Outperform Generic Solutions

Our 316 stainless steel threaded pipes deliver 92% better corrosion resistance than industry averages. See how we achieve 3,500 PSI burst strength through cold-rolled threading:

| Feature |

Standard Pipes |

Our Threaded Pipes |

| Thread Precision |

±0.015" |

±0.003" |

| Pressure Rating |

1,200 PSI |

3,500 PSI |

Manufacturing Precision You Can Feel

While other threaded pipe fittings manufacturers use basic CNC machines, we deploy 5-axis robotic threading systems. Result? Threads so smooth you can screw connections by hand - yet strong enough for offshore oil rigs.

Custom Solutions

Need 1/8" NPT to 2" BSP adapters? We'll prototype your threaded metal pipe fittings in 72 hours flat.

Proven Performance

97% of clients report zero leaks after 5+ years using our stainless steel threaded pipes.

Your Move: Keep Band-Aiding or Solve It Forever?

“

After switching to their threaded pipe system, we reduced maintenance costs by $142,000 annually. Why didn't we do this sooner?

- PetroTex Energy Project Manager

Ready for Leak-Proof Confidence?

Get your custom threaded metal pipe quote in 8 minutes - complete with 3D threading diagrams and stress simulations.

Claim Your Free Pipe Audit →

Limited to first 17 responders this week

(threaded metal pipe)

FAQS on threaded metal pipe

Q: What are the main applications of threaded metal pipes?

A: Threaded metal pipes are widely used in plumbing, gas lines, and industrial systems for secure connections. Their threaded design ensures leak-resistant joints, making them ideal for high-pressure environments.

Q: How to identify reliable threaded pipe fittings manufacturers?

A: Look for manufacturers with certifications like ISO or ASTM, and check reviews for quality consistency. Reliable suppliers often provide material test reports and custom threading options.

Q: What advantages do stainless steel threaded pipes offer over other materials?

A: Stainless steel threaded pipes resist corrosion, handle extreme temperatures, and last longer in harsh conditions. They’re preferred for chemical, marine, and food-grade applications.

Q: Can threaded metal pipes be reused after disassembly?

A: Yes, if threads remain undamaged during removal. Use thread sealant during reinstallation to maintain integrity. Avoid reusing pipes with stripped or worn threads.

Q: What standards govern stainless steel threaded pipe production?

A: Common standards include ASME B1.20.1 for threading and ASTM A312/A269 for material quality. Compliance ensures compatibility with fittings and system safety.