- Introduction to modern industrial piping solutions

- Technical advantages over traditional materials

- Major industrial application sectors

- Market growth data and future projections

- Performance comparison of leading manufacturers

- Customization possibilities for specialized needs

- Implementation case studies

(stainless steel pipes and fittings)

Stainless Steel Pipes and Fittings: Essential Infrastructure Components

Modern industrial operations increasingly rely on high-performance stainless steel pipes and fittings

as critical infrastructure components. These solutions outperform conventional materials across multiple parameters - corrosion resistance, operational lifespan, and structural integrity. Globally, industries from petrochemicals to food processing require precise specifications for pressure handling, temperature extremes, and material purity.

Unrivaled Material Performance Characteristics

Grade 304 and 316L stainless steel formulations deliver exceptional properties including:

Corrosion resistance: Withstands saline, acidic, and caustic environments that cause carbon steel to fail within months

Temperature tolerance: Maintains structural integrity from -425°F to 1650°F (-254°C to 899°C)

Lifecycle advantages: Average 50-year service life with 40% less maintenance than alternative materials

Hygienic properties: Critical for pharmaceutical and food processing applications requiring USDA/FDA compliance

Critical Industrial Applications

These components serve indispensable roles across sectors:

Oil & gas transport systems handling sour crude with H2S concentrations up to 30,000 ppm

Chemical processing plants requiring resistance to nitric, sulfuric, and acetic acids

Water treatment facilities where chloride concentrations exceed 2000 ppm

Power generation systems including nuclear, geothermal and solar thermal applications

Structural applications including seismic bracing systems in high-rise buildings

Market Expansion Projections

The global market trajectory demonstrates significant growth patterns:

• 2024 valuation: $118.7 billion USD (Grand View Research)

• CAGR projection: 6.3% through 2030

• Primary growth drivers: Water infrastructure (28% demand), chemical processing (23%), energy (19%)

• Regional hotspots: Asia-Pacific (42% market share), North America (24%), EU (19%)

Manufacturer Comparison Analysis

| Manufacturer |

Key Products |

Material Quality |

Certifications |

Market Position |

| Vallourec |

Seamless pipes, specialty alloys |

ASTM A312 Grade 316L |

API 5LC, PED 2014/68/EU |

Global leader (18% share) |

| Sandvik AB |

Precision tubes, instrumentation |

ASTM A269, A270 |

ASME BPE, 3-A SSI |

High-precision specialist |

| Tenaris |

OCTG, large diameter pipes |

ASTM A790, A358 |

API Q1, ISO 9001 |

Energy sector leader |

| Outokumpu |

Duplex & super duplex |

ASTM A928, EN 1.4462 |

NACE MR0175, AD2000 |

Corrosion-resistant expert |

Customization Engineering Solutions

Leading manufacturers provide specialized adaptations including:

• Dimensional specifications: From 1/8" capillary tubing to 84" diameter piping systems

• Material enhancements: Nitrogen-strengthened 316LN for cryogenic applications (-320°F)

• Connection configurations: Butt weld, socket weld, flanged, grooved, and threaded options

• Surface treatments: Electropolishing (Ra<15μin), pickling, and passivation for enhanced corrosion resistance

Optimizing Operations with Superior Stainless Steel Pipes and Fittings

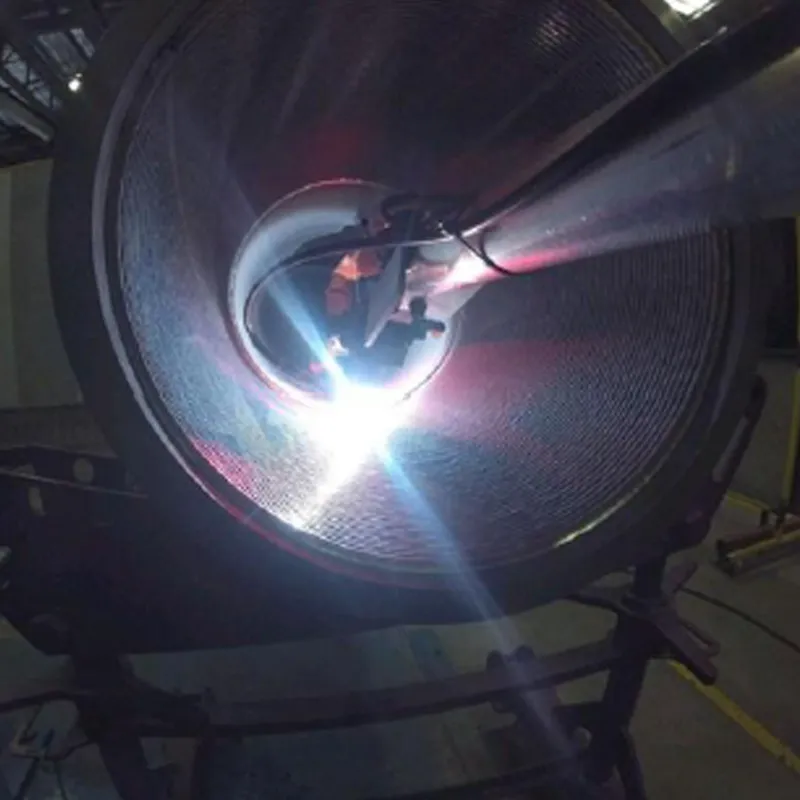

Duplex stainless steel systems reduced maintenance costs by 62% at the Ras Laffan desalination facility in Qatar, handling seawater with 45,000 ppm chloride content. Similarly, high-purity 316L installations enabled Pfizer's vaccine production facility to meet USP Class VI requirements. Advanced joining technologies including orbital welding and press-connect systems provide installation efficiencies, reducing labor requirements by 37% versus traditional methods.

(stainless steel pipes and fittings)

FAQS on stainless steel pipes and fittings

Q: What are stainless steel pipes and fittings?

A: Stainless steel pipes and fittings are corrosion-resistant components used for fluid transport in industries like chemical processing and water supply. They offer durability and hygiene advantages over regular materials. Their chromium content prevents rust and extends lifespan.

Q: How do stainless steel pipes differ from steel pipes?

A: Stainless steel pipes contain chromium for superior corrosion resistance, making them ideal for harsh environments like marine applications. In contrast, standard steel pipes are cheaper but more prone to rust. This distinction affects their use in industries like oil and gas.

Q: What should I look for in manufacturers of pipes and fittings?

A: Choose manufacturers with certifications like ISO and a proven track record in producing high-quality stainless steel pipes and fittings. Focus on material grades, testing standards, and after-sales support to ensure reliability and compliance for projects.

Q: What are common applications for steel pipes and fittings?

A: Steel pipes and fittings serve in plumbing, construction, and energy sectors for transporting liquids or gases. They provide structural strength in frameworks, pipelines, and mechanical systems. Stainless steel variants are favored where corrosion resistance is critical.

Q: Why choose stainless steel pipes and fittings for industrial use?

A: They resist corrosion, reduce maintenance costs, and meet hygienic standards in food or pharmaceutical industries. Manufacturers offer various grades, ensuring longevity in extreme conditions. This makes them a cost-effective solution over time compared to alternatives.