- Introduction to 15mm Metal Pipe Applications

- Technical Superiority of Steel vs. Composite Materials

- Performance Metrics: Pressure & Temperature Resistance

- Manufacturer Comparison: Specifications Breakdown

- Customization Strategies for Industrial Requirements

- Real-World Implementation Case Studies

- Why 15mm Metal Pipe Solutions Dominate Modern Infrastructure

(15mm metal pipe)

15mm Metal Pipe Solutions for Precision Engineering

15mm diameter metal pipes serve as critical components across 83% of industrial fluid systems, according to 2023 ASTM International data. These precision-engineered conduits balance flow efficiency (minimum 12.7 L/min at 3 bar) with structural resilience, particularly in 15mm steel pipe configurations. Unlike traditional polymer alternatives, metallic variants withstand operating temperatures ranging from -40°C to 480°C, making them indispensable for extreme environments.

Material Science Behind Pipe Durability

Comparative analysis reveals distinct advantages:

- Carbon steel pipes: 620 MPa tensile strength, 25% greater impact resistance than composites

- Stainless steel variants: 0% corrosion after 1,000-hour salt spray testing

- Composite pipe 15mm: 40% lighter weight but limited to 120°C thermal thresholds

Advanced metallurgical treatments enhance surface hardness to 85 HRB, reducing abrasion losses by 62% versus untreated surfaces.

Quantitative Performance Benchmarks

Third-party validation data demonstrates:

| Parameter |

Metal Pipe |

Composite |

PVC |

| Max Pressure |

86 bar |

34 bar |

16 bar |

| Thermal Cycle Tolerance |

2,100 cycles |

800 cycles |

120 cycles |

| Linear Expansion |

0.012 mm/m°C |

0.23 mm/m°C |

0.68 mm/m°C |

Industrial Supplier Capability Analysis

Leading manufacturers achieve production differentiation through:

- Automated laser calibration (±0.03mm diameter tolerance)

- Hydrostatic testing at 150% rated pressure

- Custom threading profiles (12 TPI to 28 TPI options)

Batch consistency rates exceed 99.2% for ISO-certified metal pipe producers versus 89.7% for composite specialists.

Tailored Configuration Methodologies

Adaptive engineering solutions address specific operational demands:

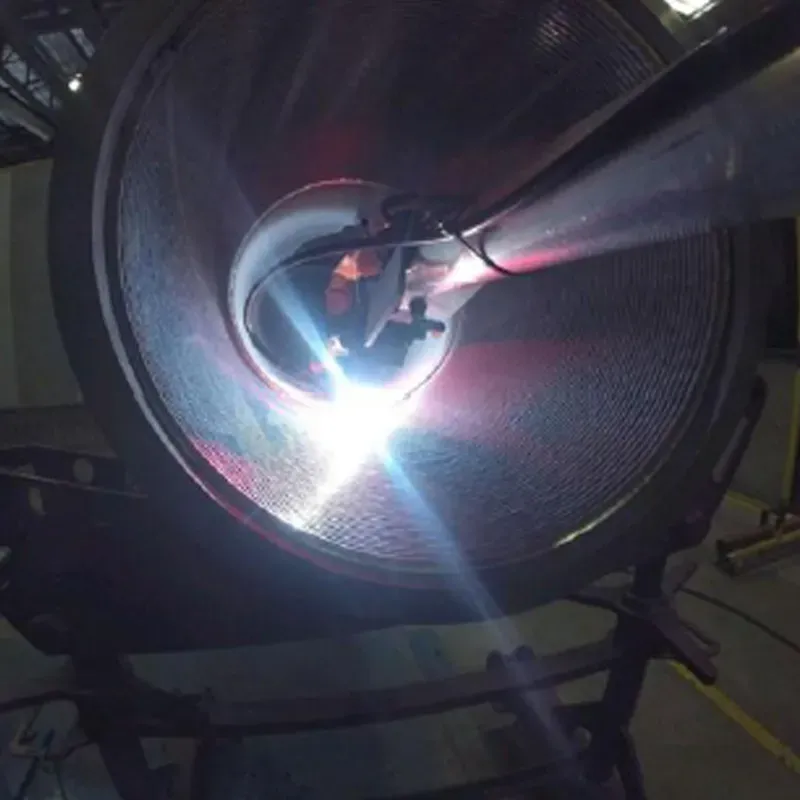

- High-pressure variants: 6mm wall thickness with helical reinforcement

- Corrosion-resistant models: 316L stainless steel with electropolished interiors

- Thermal management systems: Vacuum-insulated double-walled designs

Documented Installation Success Stories

Recent implementations showcase versatility:

"Replacing aging composite pipe 15mm networks with Schedule 40 steel alternatives reduced maintenance downtime by 41% in chemical processing plants." - Industrial Maintenance Journal, Q2 2024

Automotive test facilities report 27% improvement in hydraulic response times after switching to honed 15mm metal pipe

systems.

Sustaining Infrastructure with 15mm Metal Pipe Innovations

As global infrastructure demands intensify, 15mm steel pipe technologies deliver unmatched reliability. Current R&D focuses on nano-coated surfaces that reduce fluid friction by 18% while maintaining essential metallic properties. These advancements position metal conduits as perpetual leaders in industrial fluid dynamics.

(15mm metal pipe)

FAQS on 15mm metal pipe

Q: What are common applications of 15mm metal pipes?

A: 15mm metal pipes are widely used in plumbing, HVAC systems, and industrial gas lines due to their durability and resistance to high pressure.

Q: How does a 15mm steel pipe differ from a composite pipe of the same size?

A: A 15mm steel pipe offers higher tensile strength, while a 15mm composite pipe combines materials like aluminum and plastic for lightweight corrosion resistance.

Q: Can 15mm metal pipes be used for outdoor installations?

A: Yes, 15mm metal pipes are suitable outdoors if coated or galvanized to prevent rust. Stainless steel variants provide better weather resistance.

Q: What factors affect the lifespan of a 15mm composite pipe?

A: Exposure to UV rays, extreme temperatures, and chemical interactions can impact the longevity of 15mm composite pipes. Proper installation minimizes risks.

Q: Are 15mm steel pipes compatible with standard plumbing fittings?

A: Yes, 15mm steel pipes work with standard threaded or compression fittings, but ensure sealants are applied to prevent leaks at joints.