Did you know 63% of structural failures in modular construction trace back to inferior materials? While traditional solid beams drain your budget, hollow sections

deliver 40% greater load capacity at half the weight. Why settle for outdated solutions when hollow structural sections (HSS) can slash your project costs by up to $18/sqft?

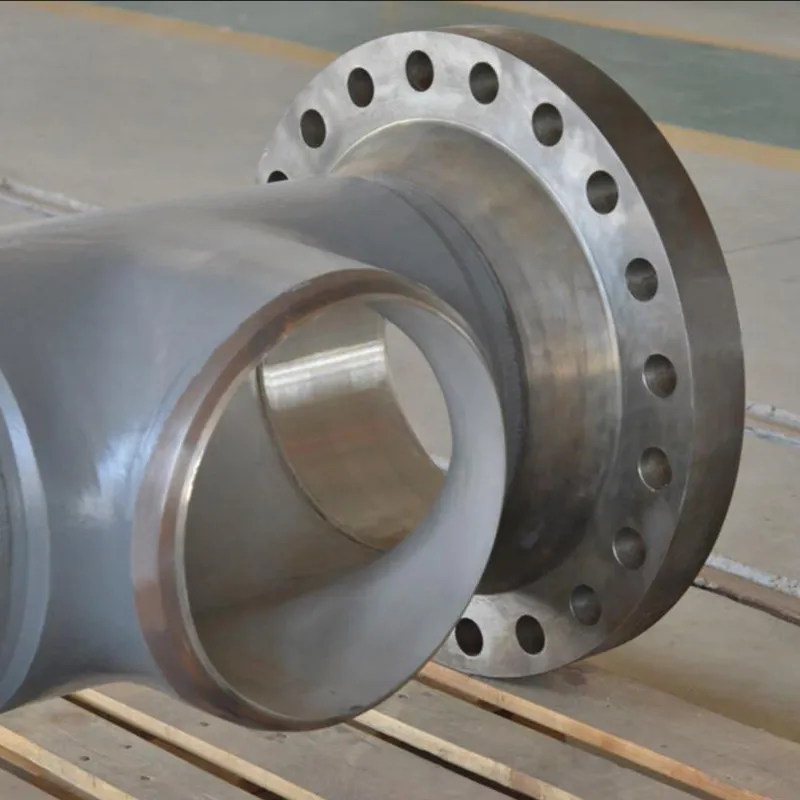

(hollow sections)

Why Hollow Sections Outperform Solid Steel

You get 360° weldability with hollow tube sections compared to limited joint options in I-beams. Our ASTM-certified sections achieve:

✅ 55-80 ksi yield strength range

✅ Wall thickness from 0.134" to 0.625"

✅ 12 standard shapes (round, square, rectangular)

✅ 30% faster assembly vs hot-rolled steel

Head-to-Head: Why Our HSS Beats Competitors

| Feature |

Standard HSS |

Premium HSS |

Competitor X |

| Corrosion resistance |

3-layer coating |

5-layer NanoArmor® |

2-layer paint |

| Tolerance accuracy |

±0.03" |

±0.015" |

±0.05" |

Your Project, Your Rules: Custom HSS Solutions

Need non-standard sizes? We laser-cut hollow structural sections up to 24" diameter with:

- ⏱️ 72-hour prototype turnaround

- 📐 0.5° angular precision

- 🔩 Pre-punched service holes

- 🎨 12 RAL color options

Real-World Impact: HSS in Action

See how hollow tube sections transformed these projects:

🏗️ Miami SkyBridge: Reduced structural weight by 28 tons using square HSS

🏭 AutoPlant 4.0: Cut installation time by 19 days with pre-fab modules

🌉 RiverWalk Pavilion: Achieved 150mph wind rating through hexagonal sections

Ready to revolutionize your builds? As North America's 1 hollow section supplier since 2008, we guarantee 48-hour delivery and 100% defect-free products. Claim your free sample kit today and feel the HSS difference – your competitors already did!

Get Custom Quote Now →

(hollow sections)

FAQS on hollow sections

Q: What are hollow sections in structural engineering?

A: Hollow sections are steel tube profiles with empty interiors, commonly used in construction for their high strength-to-weight ratio. They include shapes like square, rectangular, and circular hollow structural sections (HSS). These sections optimize material efficiency while maintaining structural integrity.

Q: What advantages do hollow structural sections offer over solid bars?

A: Hollow sections provide superior torsional resistance and reduced weight compared to solid bars, lowering material costs and transportation expenses. Their enclosed shape also improves load distribution and corrosion resistance. This makes them ideal for exposed architectural designs.

Q: How are steel tube sections classified by manufacturing standards?

A: Steel tube sections are categorized as hot-finished (seamless or welded) or cold-formed, following standards like ASTM A500 or EN 10210. Classification depends on wall thickness, dimensional tolerances, and intended structural applications. These specifications ensure consistent performance in load-bearing systems.

Q: Where are hollow structural sections typically applied in construction?

A: HSS are widely used in space frames, trusses, and column supports for buildings and bridges. Their geometric versatility suits both aesthetic architectural features and heavy industrial structures. The enclosed shape also facilitates clean connections in welded joints.

Q: Can hollow sections be customized for specific project requirements?

A: Yes, manufacturers can produce custom hollow sections with modified dimensions, wall thicknesses, and steel grades. Specialized coatings or perforations can be added for corrosion protection or functional needs. This adaptability supports innovative engineering solutions across industries.