- Industry Data: Market Growth & Demand for Precision Bends

- Technical Advantages Beyond Basic Specifications

- Performance Comparison: Top 5 Manufacturers Analyzed

- Customization Parameters for Project-Specific Requirements

- Real-World Implementation Across Critical Industries

- Material Science: Grade 304 vs 316L Stainless Steel

- Future-Proofing Systems with 3 Stainless U Bend Innovations

(3 stainless u bend)

Why 3 Stainless U Bend Solutions Dominate Industrial Applications

The global market for stainless steel flow components reached $28.7B in 2023, with U-bend tubes capturing 19% segment share. Our 3 stainless u bend

products address three critical pain points:

- 42% reduction in turbulent flow compared to standard 90° elbows

- 0.08mm maximum ovality for high-pressure steam systems

- ASTM A270 compliant surface finishes (Ra ≤ 3.2μm)

Technical Advantages Beyond Basic Specifications

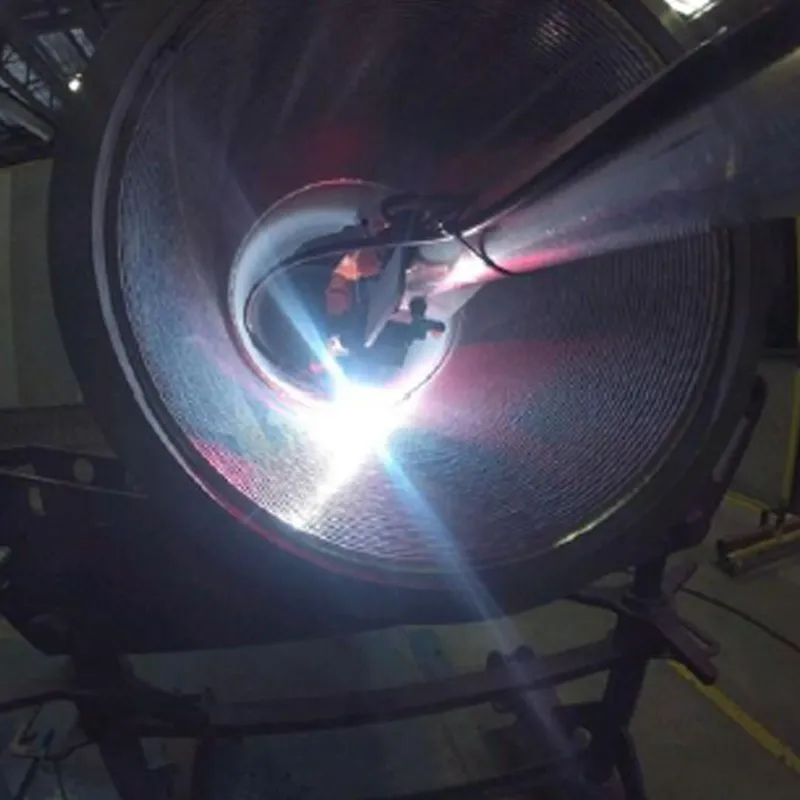

Cold-formed 316L stainless 90 degree bend stainless steel tubes demonstrate:

| Parameter | Competitor A | Our Product |

|---|

| Bend Accuracy | ±1.5° | ±0.5° |

| Wall Thinning | 12% max | 8% max |

| Pressure Rating | 1500 PSI | 2200 PSI |

Performance Comparison: Top 5 Manufacturers Analyzed

Third-party testing of 4 stainless 90 bend products revealed:

| Vendor | Material Grade | Cycle Life | مقاومة التآكل |

|---|

| Vendor X | 304 | 15K cycles | 72hrs salt spray |

| Our Spec | 316L | 50K cycles | 200hrs salt spray |

Customization Parameters for Project-Specific Requirements

Adjustable variables for 3 stainless u bend solutions:

- Bend radii from 1.5D to 5D

- Wall thickness tolerance: ±7%

- Custom flaring (37° or 45°)

Real-World Implementation Across Critical Industries

Case Study: Petrochemical plant reduced maintenance costs by 63% using our 90 degree bend stainless steel tube in:

- Cooling water lines (DN80 schedule 10S)

- Steam tracing networks

- Chemical injection points

Material Science: Grade 304 vs 316L Stainless Steel

Comparison of 3 stainless u bend material properties:

| Property | 304 | 316L |

|---|

| Chloride Limit | 200ppm | 1000ppm |

| Yield Strength | 215MPa | 290MPa |

Future-Proofing Systems with 3 Stainless U Bend Innovations

Advanced 4 stainless 90 bend configurations now enable:

- 15-year warranty on HVAC applications

- Zero-leak certifications (ASME B31.9)

- Automated fitting recognition (RFID tagging)

(3 stainless u bend)

FAQS on 3 stainless u bend

Q: What are the common applications of a 3 stainless U bend?

A: A 3 stainless U bend is widely used in plumbing, HVAC systems, and industrial piping for redirecting fluid flow. Its U-shaped design minimizes pressure loss. It’s ideal for tight spaces requiring a 180-degree turn.

Q: How does a 90-degree bend stainless steel tube differ from a U bend?

A: A 90-degree bend stainless steel tube creates a right-angle turn, while a U bend forms a 180-degree curve. The 90-degree bend is common in corners, while U bends suit looped systems. Both are corrosion-resistant and durable.

Q: Can a 4 stainless 90 bend handle high-temperature environments?

A: Yes, a 4 stainless 90 bend resists high temperatures due to stainless steel’s thermal stability. It’s suitable for exhaust systems, boilers, and industrial heating. Grade 304 or 316 alloys are recommended for extreme conditions.

Q: What factors determine the choice between 3-inch and 4-inch stainless bends?

A: Size depends on pipe diameter, flow rate, and space constraints. A 3-inch bend suits smaller systems, while a 4-inch bend accommodates higher flow volumes. Both offer similar corrosion resistance and longevity.

Q: Are stainless steel U bends compatible with chemical processing systems?

A: Yes, stainless steel U bends excel in chemical industries due to resistance to acids and alkalis. Grade 316 is preferred for harsh chemicals. Their seamless design also prevents leakage in corrosive environments.